Why does mold thrive in building materials?

Mold. An invisible enemy at first, but by the time visual cues let you in on the problem, it’s likely caused some irreversible damage to its host surface. While mold spores are naturally occurring all around us, the issue manifests when these spores drop onto places with excessive moisture and a nutrient source, allowing the mold to grow and flourish.

In both residential and commercial buildings, mold can find a number of places that meet these conditions. We all know the struggle of combatting mold in toilets, sinks, and tile grout, but what about the structural areas we can’t see? Mold can hide in foam insulation and piping, on roofs, underneath floors and carpet, and even behind wallpaper. Once moisture has settled into a surface, it only takes 24-48 hours for mold to form.

Building materials typically contain starches, organic adhesives, and cellulose sugars, making them more susceptible to the impacts of mold growth over time. It’s estimated that 70% of homes in the United States experience uninhibited mold growth, and between trapped moisture, temperature fluctuation, and nutrient dense materials – it’s no surprise.

Antimicrobial materials are just 'built different'

Once mold growth has made its presence apparent in or outside a building (likely in the form of dark greenish-black, rust, or pink stains), it can be difficult to reverse. Sometimes regular cleaning methods can’t keep up with the persistent growth, and it’s likely that the surface the mold is growing on is no longer salvageable. Beyond replacing damaged materials, mold remediation will typically cost the average homeowner anywhere from $1,120 to $3,325, leaving it impractical and costly to cope with fungal growth by turning over building materials like drywall, supports, insulation, flooring foundations.

Integrating antimicrobial technologies into building materials is a keyway to help prevent these issues before they can start, disrupting mold growth the moment spores come into contact with the surface. By manufacturing these materials with built-in antimicrobial product protection, both the material itself and construction investments are protected from the deleterious effects of mold and bacteria growth.

The primary purpose of enhancing building materials with antimicrobial technology is the protect building products from premature degradation caused by microbes, which leads to multiple positive benefits for structures and end users. This benefit is not to be confused with public health benefits. Read more about this topic by clicking the link below.

From the ground up

Corks, foams, and fabric layers that support hard flooring and carpets quite literally lay the groundwork for unwelcomed guests to set up camp. Lack of ventilation combined with trapped moisture, adhesives and other complex materials create an optimal environment for fungal growth that can lead to stains, musty odors, and product deterioration.

Manufacturing foam underlay and other flooring installation materials with built-in antimicrobial technology provides an added layer of product protection that can help prevent mold growth before it’s too late to fix. Microban partners with a number of flooring material manufacturers to help change the landscape of bacteria and fungal issues from the surface to the underlay by creating an inhospitable environment for microbes to survive.

If these walls could talk, they'd ask for antimicrobial insulation, grouts, and paints

Walls are susceptible to fungal growth both internally and externally, especially in humid areas of the home like bathrooms and laundry rooms. Cellulose materials and paper-based products are particularly conducive for mold growth, allowing for mold to prosper within drywall and underneath wallpapers and cause structural damage that can go unnoticed from the living space. Coating walls with an antimicrobial paint is a simple way builders can enhance spaces with an added layer of protection that reduces the ability for moisture and fungal build up to penetrate the wall surface.

Other structural support materials like grouts and sealants are typically exposed to high humidity and fluctuating temperatures that lead to unsightly fungal growth. Regular cleaning practices sometimes aren’t enough to keep up with the rate of growth on these materials, often disrupting aesthetics and cleanliness across shower tile, backsplashes, and counters. An added level of built-in antimicrobial protection offers a permanent, proactive solution by reducing microbes before they start to flourish.

Top it off with antimicrobial protection for PVC roofing materials and more

Building exteriors don’t escape when it comes to unwanted microbes, particularly when it comes to roofing. While the elements and harsh weather patterns alone can threaten the durability of roofing structures, outdoor conditions can encourage another damaging phenomenon: fungal growth. UV exposure, humidity, and fluctuating temperatures support an optimal environment for mold, mildew, and algae growth.

Historically, arsenic-based biocides have been used to confront this issue, but new regulations have called to reduce concentrated levels of these additives to address undesirable toxicity levels and their effects on human health and the environment [1]. In a 2014 roofing assessment performed by the Washington Department of Ecology, rainwater runoff was found to contain arsenic levels that ranged from 22 and 117 ug/L [2].

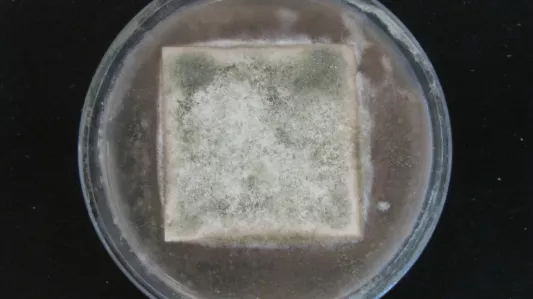

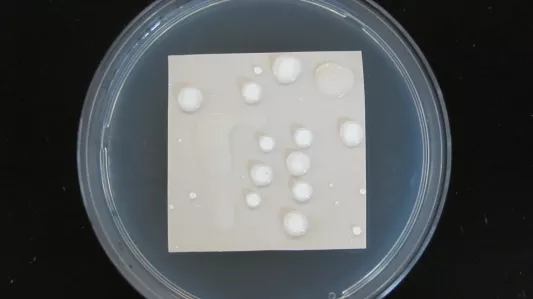

Untreated PVC Roofing Membrane

Microban® Treated PVC Roofing Membrane

Microban offers newer, environmentally responsible formulations that address fungal growth on PVC roofing membranes without the use of heavy metals. Our unique, double-active solution provides broad-spectrum antimicrobial control in harsh environments and remains globally registered for use in a variety of applications.

Contact a team member to learn more about our technologies and weather-testing options for PVC roofing membranes.

Be it in homes, schools, offices, or commercial spaces, Microban can enhance materials that make up the buildings where we live, work, and play. Built-in antimicrobial protection allows for inherently cleaner spaces that look better and last longer, offering stronger and more durable options to builders, home renovators, DIY-duos, and more.

Ready to redefine building materials? Let's partner together.

[1] OPBA Interim Registration Review Discussion, Case Number 0044 § IV.A (June 2021)

[2] Department of Ecology. (2014). Roofing Materials Assessment: Investigation of Toxic Chemicals in Roof Runoff. State of Washington. https://fortress.wa.gov/ecy/publications/SummaryPages/1403003.html