Transportation

High-traffic surfaces on buses, trains, and airplanes often serve as a breeding ground for microbes. Microban technology protects against harmful bacteria, mold, and mildew growth, delivering added peace of mind in the transportation industry.

Food Service

Built-in antimicrobial technology for food contact surfaces enables food industry professionals to maintain cleaner environments for storing, delivering, processing, preparing and serving food consumed by people and animals.

Construction

Building materials often contain starches, organic adhesives, and cellulose sugars that represent ideal nutrient sources for microbial growth. Antimicrobial technology can be integrated into polymeric building materials to promote cleaner, greener buildings.

SilverShield® is a range of silver-based antibacterial technologies for plastics. The proven formulations operate a multi-modal attack, eliminating up to 99.9% of bacterial growth.

MicroGuard™ is a range of metal-free antifungal technologies for PVC, PU and EVA foam applications. The line presents an alternative to arsenic-based formulations such as OBPA.

Coming from chemistry inspired by nature, Ascera™ is a sustainable antibacterial technology designed for olefinic polymers and solvent-based coating applications.

Active 24/7

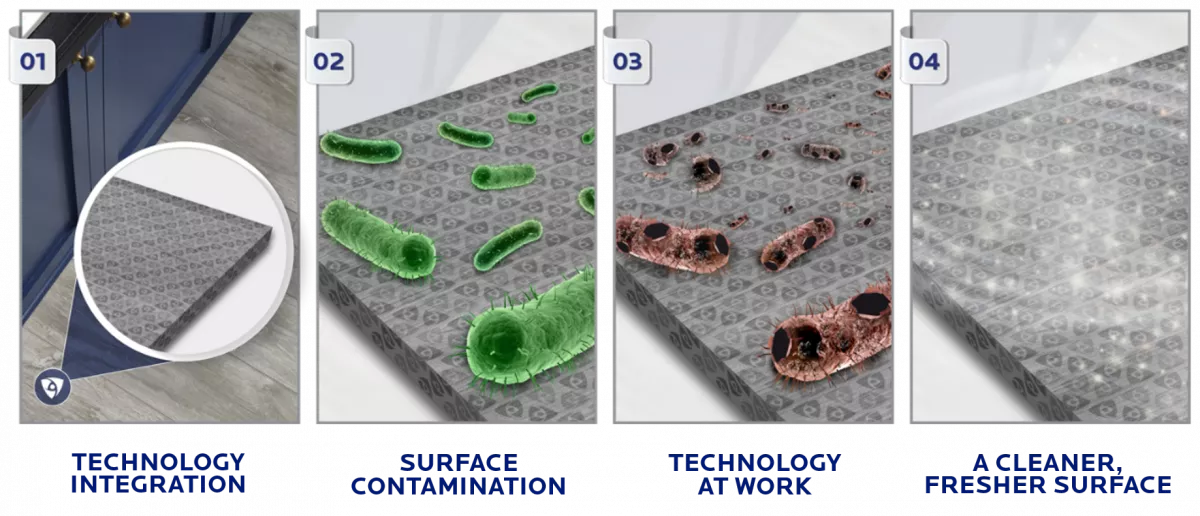

Microban protection is a permanent, cost-effective solution that remains active for your plastic product's expected lifetime.

Cleaner

Microban protection creates inherently cleaner and more durable plastic products that work to complement regular cleaning.

Antibacterial*

Microban protection has been proven to reduce harmful bacterial growth on plastics. Tested strains include E. coli and MRSA.

Antifungal*

Microban protection works to prevent the growth of unsightly mold and mildew, helping improve product longevity and performance.

Stops the stink

Microban protection preserves the aesthetics of your plastic product by minimizing the presence of stain and odor-causing bacteria.

Sustainable

Microban protection actively inhibits the growth of degrading microbes, helping extend product lifespan and minimizing waste.

Safe to use

Microban protection has undergone extensive independent laboratory testing and has a long history of safe use in plastic products.

Food contact*

Selected Microban technologies are listed on EFSA, registered with the EPA, and permitted for use by the FDA in food-contact articles.

Tried & trusted

Microban protection is used and trusted by some of the world's leading product manufacturers, including Speck and GE Appliances.

Frequently Asked Questions

What is the key difference between plastics and polymers?

Polymers can exist organically or be created synthetically. They consist of chains of joined individual molecules or monomers. By contrast, plastics are composed of chains of polymers that can be partially organic or fully synthetic.

What are common antimicrobial technologies for plastics?

A range of antimicrobial technologies are suitable for integration into plastics. Common active ingredients include silver and zinc. There are other actives available that are based on non-heavy-metal and metal-free formulations.

What are common applications for antimicrobial plastics?

Common applications for antimicrobial plastics include food storage containers, water tanks, phone cases, water bottles and chopping boards.

What are the key benefits of antimicrobial technologies for plastics?

Antimicrobial technologies for plastics allow manufacturers to create products that are protected against microbial growth for their expected lifetime. This means the products not only stay cleaner and fresher but also last longer.

Who does Microban partner with in the plastics industry?

Microban is partnered with hundreds of brands and manufacturers that create plastic products or components. These include GE Appliances, Poly, Speck, and MacDermid.

Are Microban antimicrobial technologies for plastics safe?

Yes, Microban technologies for plastics are safe. They have undergone rigorous independent laboratory testing and are notified/registered with key regulatory bodies in both Europe and the US.

Are Microban antimicrobial technologies for plastics sustainable?

Microban offers antimicrobial technologies for plastics based on greener active ingredients.

Are some plastics inherently antimicrobial?

Yes, some plastics do have inherent antimicrobial properties. However, in order to make antimicrobial claims about a plastic product, it needs to contain a registered antimicrobial ingredient.

How do I know the technology is working in my plastic product?

Plastic products treated with Microban technology undergo regular testing to demonstrate antibacterial and/or antifungal performance.

Is Microban technology compatible with all types of polymers?

Microban technology is compatible with a broad range of polymers including ABS, PP, PE, PS, and PC.

In what forms can antimicrobial technology for plastics be suppled?

Antimicrobial technology can be supplied in a range of forms including powder, liquid and masterbatch pellet. Formulations are largely dictated by material type and manufacturing process.

Do Microban technologies influence the odor emissions of polymers?

Whilst Microban technologies actively reduce the growth of odor-causing bacteria on product surfaces, they cannot be used to prevent odor emissions in polymers during the manufacturing process.