-

Technologies

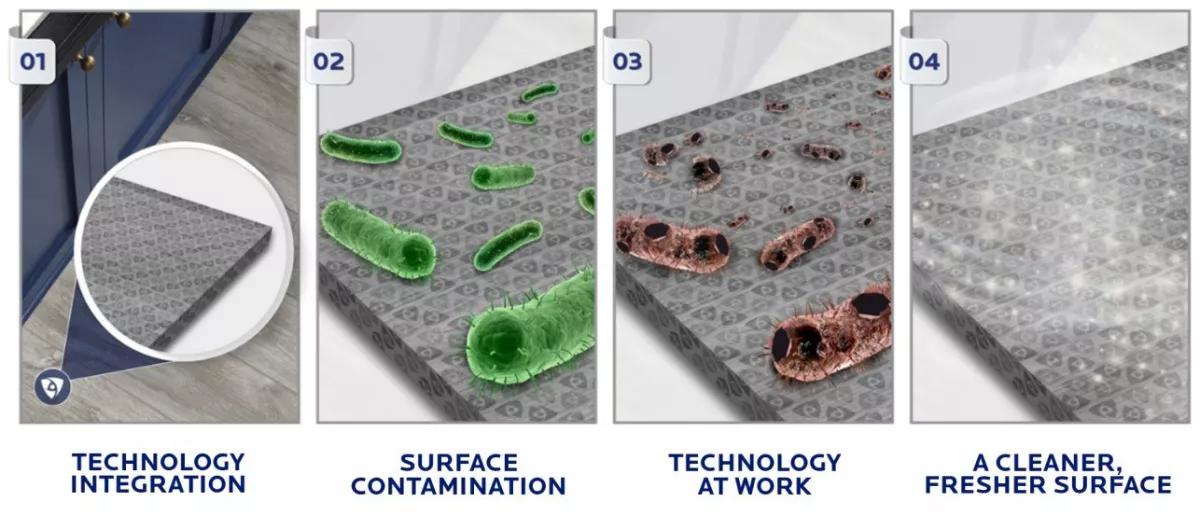

Antimicrobial

Odor Capture

Coatings

-

Services

Services

Testing

-

Partnerships

Partnerships

Working with Microban

- Resource Center

-

About Us

About Us