Creating Cleaner Car Interiors With Built-In Antimicrobial Technology

It's a well-known fact that pretty much any surface can become a breeding ground for microbes. Environmental conditions, frequent use, and cleaning lapses all contribute to the unwanted growth of bacteria, mold, and mildew. This often renders the products we love and the spaces we live and work in a little less hygienic than is perhaps desirable.

Thorough and effective cleaning is rightly cited as the primary method for creating cleaner, fresher environments. However, in many cases, repeated cleaning of a product or surface isn’t always a viable or realistic option. This is particularly true for the average automotive interior.

Cars are subjected to many contaminants on a daily basis. These include drivers, young children, animals, food deposits, and even temperature changes. It's therefore unsurprising that car interiors are often dirtier than the average toilet seat. A study published by the National Center for Biotechnology Information found more than 700 different bacteria strains living on soft and hard surfaces inside a typical vehicle. The highest number of Colony Forming Units (CFUs) were identified on the steering wheel, cup holders, and seat belts.

Whilst a weekly valet would definitely help reduce the presence of microbes in a car, what about the surfaces that are almost impossible to reach? A prime example is the air conditioning unit. Scientists at London Metropolitan University revealed that air-conditioning systems can harbour pretty nasty strains of bacteria. These include members of the Bacillus family, which can cause stomach ache, diarrhoea and even severe infections such as septicaemia.

Pulling all the facts together, it's evident that cleaning isn't enough in isolation to put the brakes on bacteria. Car owners need backup.

How Are Antimicrobial Car Treatments Added to Common Touchpoints and Hard-to-Clean Surfaces?

As a world-leading specialist, Microban® knows a thing or two about integrating antimicrobial technology into car interior surfaces. We work with both Tier 1 and Tier 2 automotive manufacturers to supply appropriate antimicrobial additives to the relevant sub-contractors.

Below, we have summarised a list of hard and soft surfaces found inside the average car and how they can be treated.

| Product/Surface | Treatment Method(s) | Can Microban® Supply Suitable Additive(s)? |

| Steering Wheel | - Impregnated polymer - In-mold coating - If leather, dye or topical sealer | Yes - view technology recommendations |

| Touchscreen | - Integrated into polymer screen - Topical coating - Treated topical polymer film | Yes - view technology recommendations |

| Control Buttons | - Impregnated polymer - In-mold coating | Yes - view technology recommendations |

| Dashboard | - Impregnated polymer - In-mold coating | Yes - view technology recommendations |

| Door Panel Interlining | - Impregnated polymer | Yes - view technology recommendations |

| Grab Handles | - Impregnated polymer - In-mold coating | Yes - view technology recommendations |

| HVAC System | - HVAC core – coating - Ducting - impregnated polymer | Yes - view technology recommendations |

| Window Rubbers | - Impregnated polymer | Yes - view technology recommendations |

| Gear Shift | - Impregnated polymer | Yes - view technology recommendations |

| Carpet | - Fibre extrusion - Topical finish | Yes - see how Phenix is doing it |

| Floor Mats | - Impregnated TPU | Yes - view technology recommendations |

| Head Liner | - Impregnated fibre - Topical finish | Yes - view technology recommendations |

| Leather | - Dye - Topical sealer | Yes - view technology recommendations |

| Seating Fabric | - Impregnated fibre - Topical finish | Yes - view technology recommendations |

| Boot Lining | - Impregnated fibre - Topical finish - Fibre extrusion | Yes - view technology recommendations |

The increasing replacement of conventional materials such as metals and glass with plastics is driving the market for antimicrobial additives in automotive interiors. Demand is also being influenced by consumer awareness of health-related issues combined with the need for longer-lasting materials.

How Does Antimicrobial Technology Work in Car Surfaces?

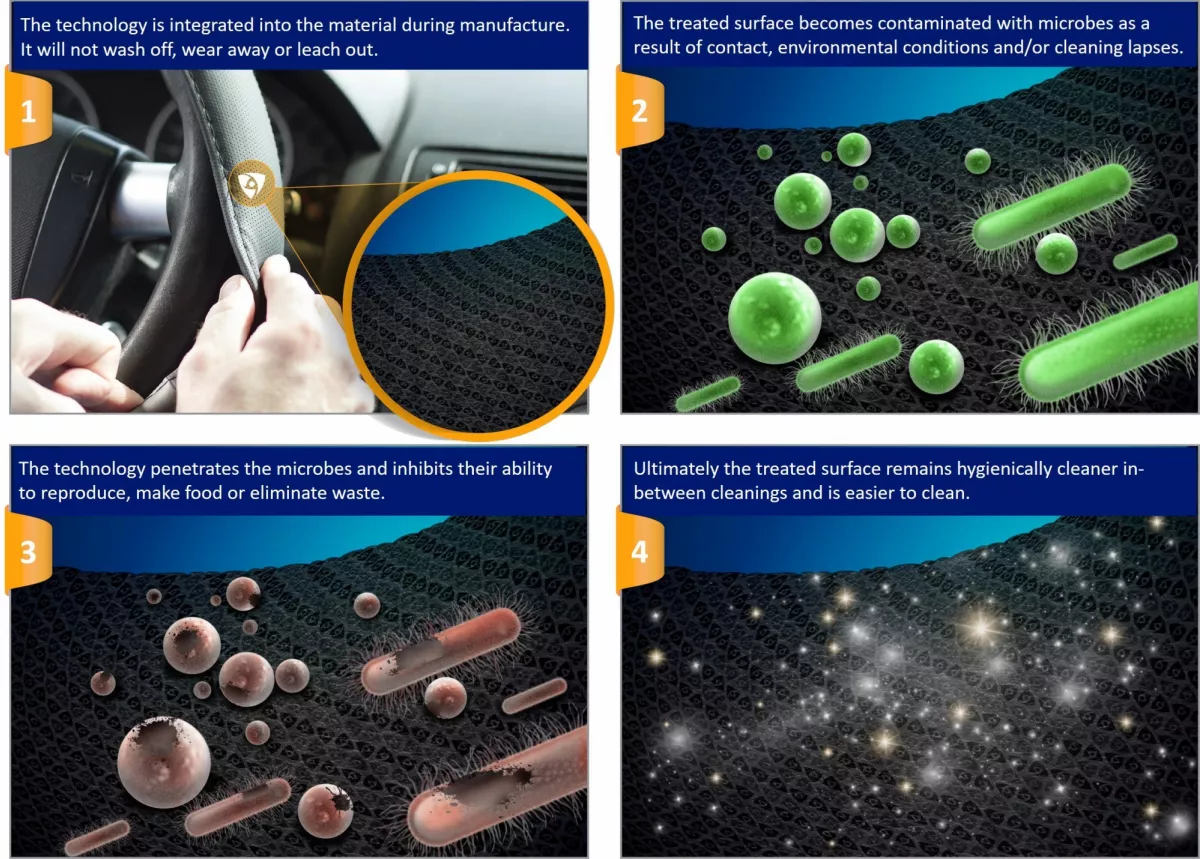

Antimicrobial car treatments work by disrupting the vital life processes and biological functions of contaminating microbes, meaning they cannot grow or reproduce on the treated surface.

What's more, because it is added during manufacture, the technology will provide durable antimicrobial protection for the expected lifetime of the product.

Is Antimicrobial Technology Expensive to Add?

The simple answer is no, but it really depends on the product.

There is a perception in the manufacturing industry that antimicrobial technology is expensive. However, this is not typically the case when considering the selling price of most finished products.

For example, it would cost no more than 25 USD in total to treat the common touch-points inside a car. Based on an average car costing approximately 25,000 USD, this would equate to 0.1% of the total selling price of the car.

What Are the Key Benefits of Interior Car Surfaces Featuring Built-In Antimicrobial Treatments?

The benefits of antimicrobial car interiors are endless. For ease, we have summarised the primary advantages below.

- Stay cleaner in-between cleaning and are easier to keep clean

- Protected from stains and odors caused by bacteria

- Perfect for use in warm climates that present the perfect environment for mold and mildew growth

- Less likely to facilitate cross-contamination from surface to surface

- More durable and longer-lasting

- Not impacted by cleaning agents and actually support regular cleaning routines

- Lifetime performance against microbial growth

- Present a low-risk investment for automotive manufacturers

What Are the Key Methods for Verifying Antimicrobial Product Performance?

Microban's experienced technical team is adept in performing antimicrobial testing. This is used to verify the antimicrobial efficacy of treated car interior surfaces. The test method employed is dependent on material type and desired product performance criteria (i.e. antibacterial vs. antifungal).

| Surface Type | International Test Protocol(s) | Test Performed by Microban®? |

| Hard (i.e. Plastic) | - Bacteria: ISO 22196 or JIS Z 2801 - Mold: AATCC TM 30 Pt III or ASTM G-21 | Yes |

| Soft (i.e. Textile) | - Bacteria: ISO 20743 or AATCC TM100 - Mold: AATCC TM 30 Pt III | Yes |

What Differentiates Microban® From Other Antimicrobial Technology Suppliers?

Experience & Partnerships

Part of Barr Brands International (BBI), Microban® has been the leading specialist in antimicrobial technologies and odor control solutions for more than 35 years. A history of success has helped us to secure winning partnerships with more than 300 companies including P&G, GE Appliances (A Haier Company), and Reebok.

Technical Excellence

Microban® fuels product innovations through our advanced technical capabilities and broad technology portfolio. Our high-performing chemistries can be manufactured into more than 50 different material types, including a range of plastics, textiles & coatings. The science behind each technology is supported by an experienced R&D team that operates across seven in-house laboratories.

Sales & Marketing Support

Microban's technological prowess is backed by a plethora of turnkey support services, delivered by a team of antimicrobial specialists. Dedicated account managers will assist with marketing claims, sales training materials, and labelling/packaging concepts, helping companies execute their new product developments in a compelling but compliant manner.

Global Footprint

Headquartered in North Carolina, USA, Microban® has operations in North America, Europe, and the Asia Pacific. Established regional offices allow us to cater to the logistical needs of partners worldwide, enhancing both the quality and efficiency of our services. Microban's global footprint also allows us to provide valuable insight into international product development, regulations, and market expansion.

Brand Dominance

Microban® is regularly cited as the most recognised antimicrobial solutions brand amongst consumers and business decision-makers. Our technologies can be found in more than 1,000 products across a variety of industry sectors. Microban's recent partnership with P&G for Microban 24 has also accelerated brand awareness, helping to strengthen our position as a household name.

Ready to Redefine Your Automotive Products?

Whether you're an automotive manufacturer or a tier supplier, contact a member of our team today to fully explore the advantages of built-in Microban® technologies.