Foam is a material of choice across a variety of industries - from its abilities to create uniform temperatures and provide support cushioning, to its noise reduction and energy absorption properties, the benefits of foam are endless.

The material is so in demand that the global polymer foam market is projected to reach $157.63 billion by 2027, exhibiting a compound annual growth rate of 7.73% across the coming years.

Foam however, like most materials, is not immune to unwanted microbial growth or the problems that accompany it.

The problem with polyurethane foam

Across consumer and commercial industries, foam is an ideal material to work with. It’s lightweight, durable, and provides protection, cushioning, and comfort to end users – yet its high susceptibility to microbial growth does the exact opposite.

Common foam applications like mattresses, flooring underlay, insulation and medical supplies all experience frequent exposure to moisture, heat, humidity, and dirt: optimal conditions for unrestrained microbial growth. In addition, these products are rarely (if ever) cleaned. By the time mold or mildew is discovered, product quality and structural safety has likely already been compromised.

The best step in addressing mold, mildew, and bacteria in foam products is prevention. Foams manufactured with built-in antimicrobial solutions work at a cellular level to continuously stop the growth of microbes before it starts.

What is antimicrobial foam?

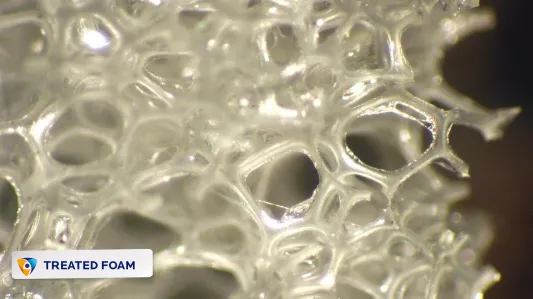

Microban® offers a range of antimicrobial technologies that can be added into directly into foam at the stage of manufacture. Once integrated into the material, the antimicrobial properties last the lifetime of the product, so foam used in bedding, floor underlay and automotive interiors become inherently resistant to unsightly microbial growth.

When microbes come into contact with treated foam, Microban® technologies go to work. Disrupting the vital life processes of microbes, the antimicrobial inhibits the ability for stain and odor causing bacteria and mold to survive, and actively reduces the presence of microbes within the treated product.

How is antimicrobial foam manufactured?

Processing conditions: Microban® additives can be added directly into the liquid polyol prior to the polymerization process, compatible with existing manufacturing processes.

Regulatory approvals: Microban® antimicrobial additives are registered with the Environmental Protection Agency (EPA) and notified with the Biocidal Products Regulation (BPR).

Testing considerations: Our development teams work directly with manufacturers to determine and perform the appropriate antimicrobial efficacy testing needed for each product application. Different industries may hold foams to certain criteria, including:

ASTM G21: marine, automotive, furniture, bedding

ASTM E1428: marine

Benefits of manufacturing foam with Microban® antimicrobial technology

- Microban® becomes permanent part of the foam, actively reducing the growth of unwanted bacteria, mold and mildew

- Extends useful life of foam products, promoting sustainability initiatives

- Improves foam quality, durability and performance

- Helps prevent stains, odors and premature product degradation caused by bacteria, mold and mildew

- Offers unique value and competitive edge across a variety of product applications

Common antimicrobial foam applications

Microban is currently partnered with various industry leaders to address the issues of unwanted microbial growth in foam products.

Armacell: Antimicrobial Commercial Foam Insulation

Armacell recognized a need to combat microbial proliferation in their foam insulation products to preserve structural integrity and protect indoor air quality. Armacell integrates Microban® antimicrobial technology into their AP ArmaFlex insulation products to actively inhibit the growth of stain and odor causing mold and mildew.

Torlys: Antimicrobial Foam Flooring Underlay

Foam is ideal for offering natural air cushioning, insulation and sound absorption under flooring, but can be a prime spot for unseen fungal growth. Torlys’ FoamPlus™ Blue Underlay with Microban® gives consumers greater peace of mind and helps prevent fungal growth beneath floor surfaces.