Antibacterial Ceramic Tiles By Panariagroup and Microban®

Panariagroup Industrie Ceramiche S.p.A. is a multinational manufacturer of luxury ceramics for floor, wall and other surface applications. Located in the “ceramic district” of Italy between Modena and Reggio Emilia, the group operates through eight brands and has specialised in ceramics production for over 30 years.

With around 1,800 employees and six manufacturing plants, Panariagroup ranks among the main national and international producers in its sector, distributing its products in more than 100 countries through a sales network made of 500 employees and 300 agents serving a base of about 9,000 partners.

PROTECT by Panariagroup: Be Happy on the Floor

The relationship between Panariagroup and Microban International demonstrates the company's unfaltering commitment to staying at the cutting edge of ceramics innovation.

The extensive work at the Panariagroup Research Centre in conjunction with Microban® has culminated in the creation of PROTECT, a range of ceramic floor and wall tiles enhanced with antibacterial product protection.

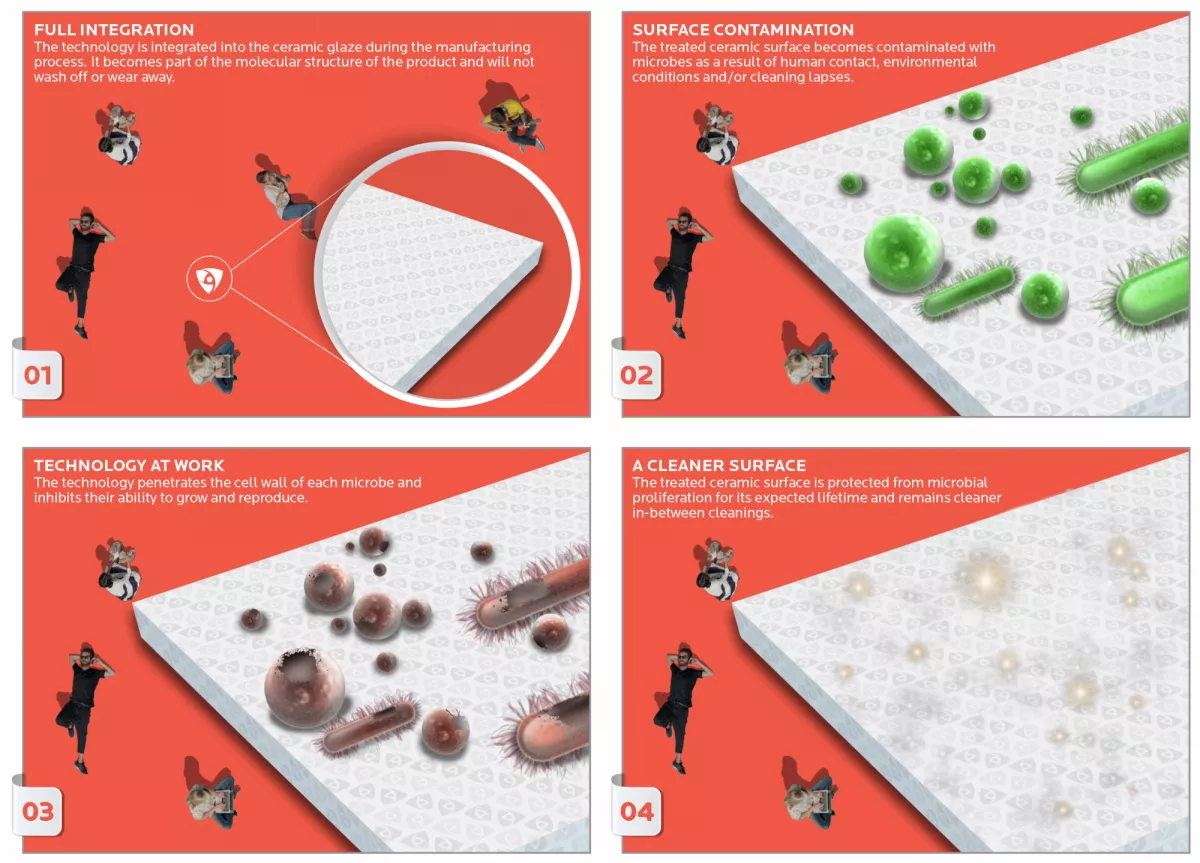

How Does Microban® Technology Work in PROTECT Tiles?

Integrated at the stage of manufacture, Microban® 3G Silver™ technology works to eliminate up to 99.9% of bacterial growth on the treated tiles. Thanks to Microban®, PROTECT tiles are consistently protected, with improved levels of hygiene, unalterable from wear and tear and climatic conditions.

Key Benefits of PROTECT Ceramic Tiles Enhanced With Microban® Technology

- Powerful Antibacterial Properties: protected from the growth of harmful and degrading bacteria by up to 99.9%

- 24/7 Product Protection: the antibacterial shield in PROTECT tiles is always active, day and night

- Lifetime Performance: antibacterial technology remains active throughout the life cycle of the ceramic tile and guarantees a high level of product protection in-between cleaning.

- Guaranteed Quality: PROTECT is guaranteed by the partnership with Microban®, the world’s leading specialist in safe and effective antimicrobial technology. Furthermore, the antibacterial technology manufactured into PROTECT tiles complies with international safety regulations and is tested by independent specialized laboratories.

PROTECT With Microban® Technology vs. TiO2

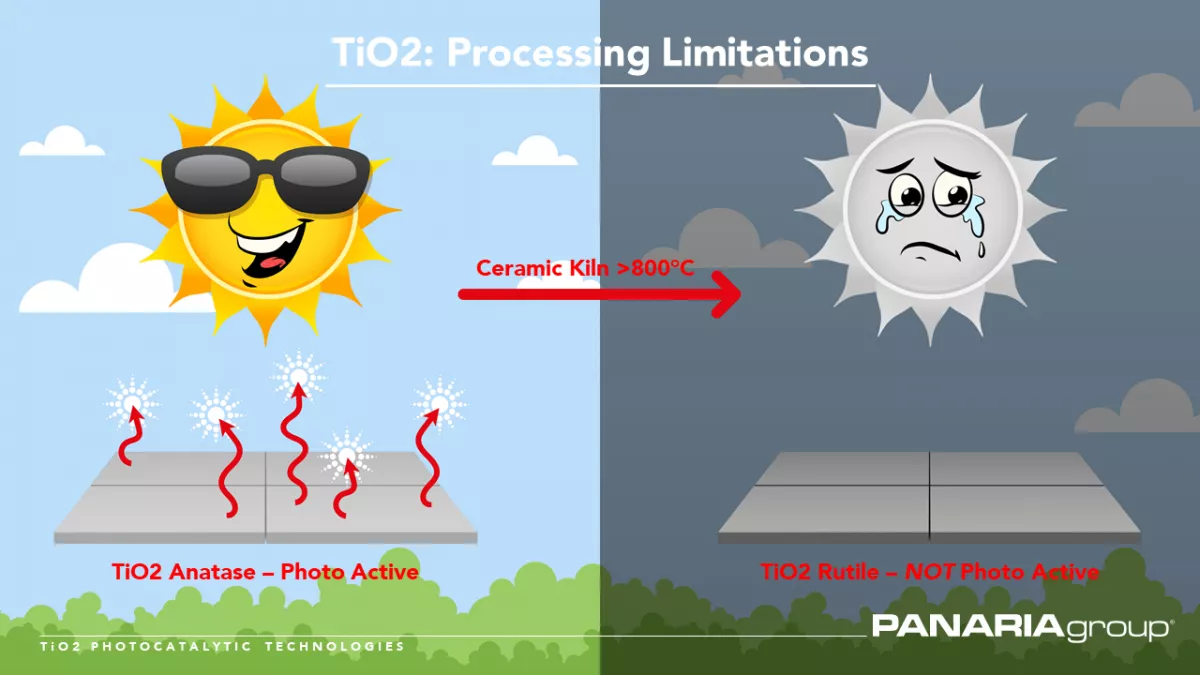

PROTECT by Panariagroup utilises proven antibacterial product protection. Unlike technologies based on Titanium Dioxide (TiO2), Microban does not require sunlight or UV rays for activation.

Titanium Dioxide Photocatalytic Technology (TiO2) is powered by sunlight, which acts on the TiO2 in the ceramic glaze. The technology claims to have antibacterial, “self-cleaning”, and pollutant removal abilities on ceramic tiles. However, research has exposed several limitations of TiO2 when compared with built-in antimicrobial ceramic technologies.

| Technology Attribute | Microban® | TiO2 |

| 24-Hour Antimicrobial | Yes | |

| Effective Indoors | Yes | |

| Effective Outdoors | Yes | Yes |

| Air Quality Neutral | Yes | |

| Ammonia Compatible | Yes | |

| Improves Cleanliness | Yes |

Combining Beauty & Hygiene With Sustainability

Panariagroup is committed to growing and creating well-being in harmony with people and the environment. The company continues to lead the ceramics industry with key sustainability initiatives, such as its recent adhesion to the United Nations Global Compact.

Microban® contributes to Panariagroup's sustainability initiatives in two ways: firstly, through the manufacturing of its antimicrobial additives, and secondly by creating cleaner and more hygienic products and surfaces that help to foster more sustainable built environments.

Sustainability in Manufacturing

The Microban antimicrobial additives that are incorporated into Panariagroup’s ceramic tile products are developed and quality controlled under Microban Products Company, an ISO 9001:2015 certified company.

Special measures are put into place during the manufacturing of these advanced antimicrobial additives to ensure sustainability considerations, including virtually no raw material waste generation in the blending process, full recovery & recycling of process water used, and the use of natural gas as the cleanest burning fuel in melt operations.

Sustainability in the Built Environment: Integrative Environmental Health

Microban® has pioneered an advanced model to illustrate the critical elements of a healthier and more sustainable built environment: Integrative Environmental Health (IEH).

Integrative Environmental Health is a collection of measures, practices and products employed in a building that contribute to better environmental conditions and ultimately promote human well-being.

All elements of IEH must be present to create the best environmental health for a building structure. A well-constructed and maintained building will not only last longer, but also minimise repair and remediation costs while presenting the best environment for its inhabitants.

In addition, a properly constructed and maintained building will consume minimal energy and minimise generation of preventable waste and chemicals such as remediation work and the need to treat areas with aggressive chemicals.

The Integrative Environmental Health model is fully in-line with green and sustainability precepts, as advocated by Panariagroup.

Other Panariagroup Brands Featuring Microban® Technology

The Panariagroup brands of Cotto d’Este, Lea Ceramiche, and Panaria all produce tiles featuring Microban® antibacterial technology, guaranteeing something more than just beauty and durability. The presence of Microban® also signifies lasting product protection, improved surface hygiene and trusted antibacterial performance for living, leisure and working environments.