NHBC estimates that a residential new build in the UK typically uses up to 8000 litres of water in the construction stage. On a global scale, The World Health Organisation (WHO) reported that dampness is estimated to affect between 10-50% of indoor environments in Europe, North America, Australia, India and Japan - whether that be from building with wet materials (i.e. laying screed floors, bricklaying, plastering and painting), poor installation and inadequate ventilation or climate conditions. Excess moisture, dampness and condensation can lead to mould growth that may not always be visible to the human eye.

The aesthetic condition of exposed building materials are a key concern to designers, builders and homeowners alike as they strongly influence resident comfort levels, but also impact the curb appeal of a building. As a result of changes in temperature and moisture in the air, peeling, cracking, and early product degradation can occur. Therefore, using more durable building materials can help to improve the quality of the built environment.

Materials that are durable and easy to maintain can also benefit the maintenance of buildings, in particular for commercial buildings like schools and hospitals, that require minimal disruption.

Why Does Mould Matter?

Cleanliness Anxieties

Under the right conditions, mould growth can weave it’s way through product structures and spread across surfaces, indicating a moisture problem in the building’s envelope or structure. Common areas for mould growth include window sills, walls, ceilings and roofing materials.

Global Warming

With energy consumption significantly driving global warming, greater attention is also being paid to the building and construction industry and the appropriate use of building materials. The focus is primarily on a product’s long-term performance. For example, thermal and sound insulation is known for its susceptibility to mould growth, making homes harder to heat and leading to a rise in energy bills.

Health Problems

Perhaps a more pressing reason to look for smarter building materials is the impact they could be having on human health. The Association of Residential Letting Agents (ARLA) reported that 2 million renters in the UK are believed to have become ill from damp-related issues found inside their homes. In support of this, the NHS advises that damp and mould in the home can lead to adverse health effects such as asthma, estimated to cost the NHS £1.1 billion each year, according to the building research body BRE.

Preventing Mould Growth Through Smarter Product Design

Building product manufacturers need to address the impact of building materials on mould growth in order to do their part in making buildings healthier for the future. Utilising smarter building materials that are actively resistant to microbes is certainly a step in the right direction.

This article looks at how building material manufacturers can develop products with both high functionality and long-term durability to help improve the cleanliness of the building all year round.

Build It Better with Antimicrobial Building Materials

Grouts and Sealants

The NHBC estimates that a working couple household will generate 180 litres of moisture from showering and 250 litres of moisture from cooking per year. Given that day to day moisture in the air is unavoidable, high levels of moisture can show telltale signs to decorative finishes including staining, rot and fungi growth.

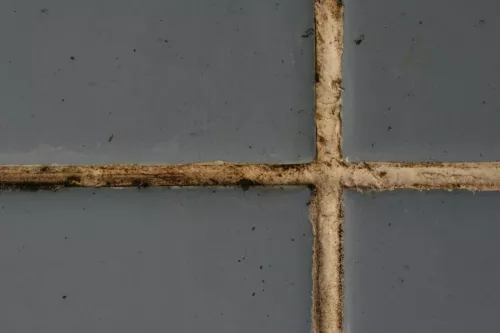

The understandable impulse from residents facing visible mould is often to battle it with soapy water and a good wipe. But even with regular cleaning, it’s hard to dispute the rapid multiplication of unsightly microbes and their ability to thrive in corner joints and crevices which is often where you will find sealants and grout, as shown in the left image.

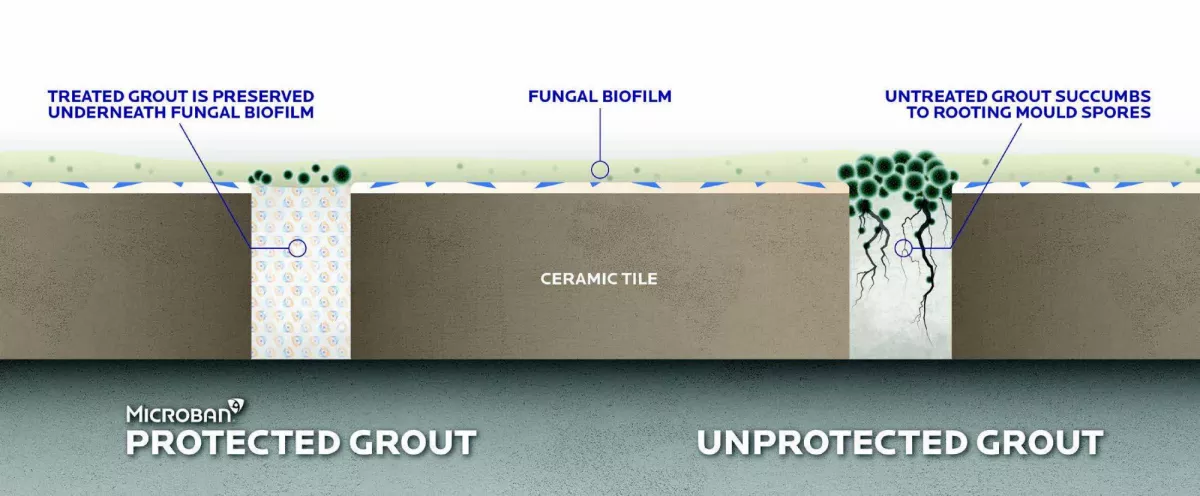

That’s where an antimicrobial sealant and grout can add long-term value to hygiene sensitive areas including residential buildings, leisure facilities, educational buildings and hospitals. Integrated during the early stages of manufacture, Microban® antimicrobial technology becomes a permanent part of the product, providing continuous 24/7 protection against damaging microbes. This makes it even easier to keep buildings looking cleaner for longer.

Accelerated by the COVID-19 pandemic, consumer demand for cleaner products is here to stay, confirms Alex Underwood, Head of Marketing at BAL Tiling Division. “Now more than ever our customers want protection against bacteria, combined with long-lasting results that maintain that ‘as new look,’ adds Alex.

Foam Insulation

Construction foam, also known as insulation foam or Polyurethane foam, is commonly used by builders to keep insulation airtight and dampen sound within residential dwellings and refurbishments, as well as in general construction. Though it can contribute to reducing energy loss in homes, foam as a building material is susceptible to mould growth which can lead to substantial material degradation.

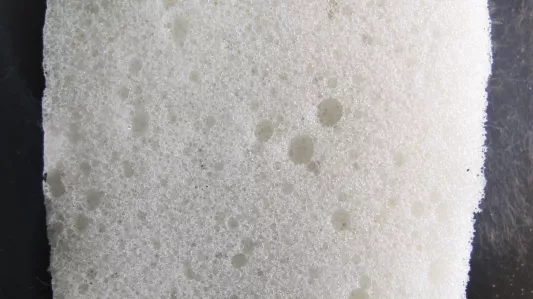

The image below on the left demonstrates what happens to foam when microbes attack. They actively break down the polymer structure, leading to diminished performance when it comes to building insulation. The image on the right shows polyurethane foam enhanced with antimicrobial technology.

Built-in antimicrobial protection provides added security for construction foams, delivering enhanced longevity, cleanliness and performance.

Shawn Dunahue, General Marketing Manager at Armacell, commented: “The antimicrobial technology from Microban really drives home this differentiation by preventing the growth of mold or mildew for the lifetime of the material, and the more we can eliminate or deter microbes from living on our products, the better.”

Flooring

While it may be easier to care for flooring surfaces, it can be incredibly challenging to take care of mould growth once it penetrates the flooring structure. Telltale signs can show in the form of warping and cracking in particular with hardwood flooring and tiles, other signs may come through staining and bad odour. Once mould has set in and caused damage, it can be incredibly costly to repair.

This presents industry demand for smarter materials. Flooring products manufactured with built-in antimicrobial technology are inherently cleaner; the technology can be added to a range of material types, including finishes and underlays, and will work 24/7 to inhibit the growth of bacteria, mould and mildew - increasing product durability and lifespan.

Leading brands from the flooring industry have partnered with Microban to address consumer and commercial concerns surrounding cleanliness and hygiene:

Based in New Jersey, Mannington Mills is one of the world’s leading manufacturers of fine flooring solutions, specialising in a range of finishes for both commercial and residential buildings. In 2021, they launched an exclusive partnership with Microban to feature antimicrobial product protection across its ADURA LVT products.

Offering a complete solution to professionals and homeowners, Torlys has partnered with Microban across its smart floors and underlays. Certain floors offer 360-degree antimicrobial protection built-in to the finish, core and underlay, providing homeowners with added peace of mind so they can live more and worry less.

Granorte

Originally founded in 1972, Granorte are pioneers of innovation and sustainable flooring solutions. Granorte recognizes cork's multipurpose and high performance capabilities, and so provides a single-point solution for demanding building applications. With such a high resistance to moisture enhanced with Microban antimicrobial protection, it is the popular choice for designers and homeowners alike.