The Rise of Electronic Devices in Healthcare Environments

Anyone who has recently visited a physician’s office or hospital may have realized they were surrounded by technology. The prolific amount of technology can make it seem like you are receiving treatment in a Sci-Fi movie instead of a healthcare setting. Recent advancements in diagnostic tools, patient interface systems, and medical record maintenance have increased the technology available to healthcare professionals to provide care.

The advances in technology are designed to provide improved, faster, and less-invasive care with more efficient documentation and record sharing. The interfaces for these advances are touchscreens, tablets and cell phones. The Medical Futurist recently described the transition as “turning medicine from a paper-based into a screen-based profession.” Thankfully the days of filling out numerous paper forms prior to receiving care is slowly becoming a thing of the past.

A recent study showed the use of touchscreens for patient check-in reduced the time spent in a waiting room by 50%. These same touchscreen check-in portals can be configured to allow patients to complete documentation in their native language. Electronic based medical systems also provide the ability to request appointments, order tests, obtain results, or communicate with physicians instantaneously.

While these advancements in technology are needed and have many benefits, could they be putting patients at greater risk of infection?

One of the biggest challenges faced by the healthcare industry is infection control and prevention. The U.S. Department of Health and Human Services (DHHS) recognized healthcare associated infections (HAIs) as a serious issue and in 2009 published the National Action Plan to Prevent Health Care-Associated Infections: Road Map to Elimination.

Although significant improvement has been made by hospitals and the healthcare industry in the last 10 years, the Centers for Disease Control and Prevention (CDC) estimates “on any given day, about one in 31 hospital patients has at least one healthcare-associated infection (HAI).” Numerous organizations including the CDC and The Joint Commission have produced guidance on infection control and prevention, but until HAI’s are eliminated there is more work to be done.

The guidance and strategies for preventing the spread of infections in healthcare settings includes:

- Advantageous sanitization and disinfection formulations, used consistently and in accordance with approved use cases to fight specific sets of pathogens (such as Sani-24, the world’s first continuously active RTU disinfectant, sold by Professional Disposables International (PDI) and powered by Microban),

- Built-in antimicrobial technologies (like those in Microban’s portfolio and utilized by many manufacturers of healthcare goods and building materials worldwide)

- Correct cleaning protocols and monitoring systems that support utilization of both sets of technologies (reactive sanitization solutions and proactive built-in solutions)

Bacterial Contamination of Electronic Devices in Hospitals

Cleaning and disinfection of hospital beds, instruments, linens, floors, etc. are commonly part of a good cleaning protocol. Interestingly, touchscreens, tablets, keyboards, mouse devices, display screens, and telephones are not as commonly included in disinfection protocols. These electronic interfaces are prolific in healthcare environments and can be found in bedside portals, drug dispensing carts, x-ray screens, ultrasound screens, blood pressure cuffs, admittance portals, surgical instruments, hospital food service and many other applications.

While many of these interfaces are not specifically addressed in cleaning protocols, they are regularly taken from room to room or used on patient after patient without cleaning or disinfection. This means these surfaces might not be as clean as they could or should be, but more importantly, they also represent a mobile platform for cross-contamination from one space to the next. Multiple uses with extended periods between cleaning, or worse yet no cleaning at all, results in a higher risk of contamination from HAIs and risk of transfer to the patient and/or healthcare provider.

An additional issue in the use of technology in the medical sector, is the use of personal cell phones. A recent study showed “83% of orthopedic surgeons had pathogenic bacteria on their phones when they walked into surgery.” In another study, 100% of healthcare worker’s cell phones were contaminated with bacterial pathogens. A separate study of healthcare workers that work in operating rooms or intensive care units (ICUs) identified 89.5% of the participants never cleaned their mobile phones. Unfortunately, no amount of handwashing will prevent cross contamination from a phone contaminated with bacteria. If personal cell phones are going to be allowed in healthcare settings, they need to be included in infection prevention protocols.

Built-In Antimicrobial Technology & Infection Control

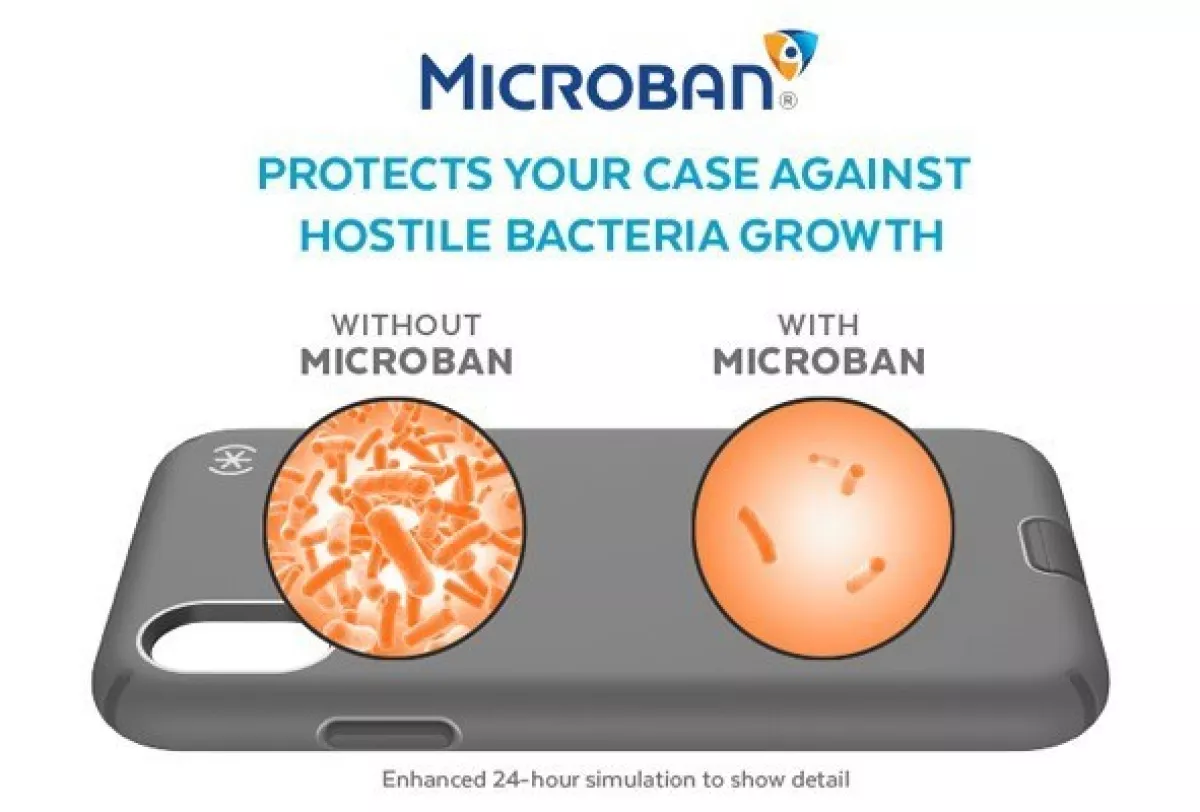

To help address the issue of mobile phone surface protection, Microban is partnered with one of the leaders in the mobile space, Speck Products. Speck Products is an industry leader in distinctive and innovative products for the world’s top smartphones, tablets, laptops, watches, and backpacks. One of Speck’s best-selling products is its Microban-protected Presidio SPORT cell phone cases.

In addition, Microban technology is hard at work across many other products in the healthcare space, including:

- Crash carts, shelving, and storage units by Intermetro;

- Medical curtains by Marlux Medical;

- Scales by SR Scales;

- Medication management carts and workstations by Touchpoint Medical;

- Stand up desks and a massive range of office accessories by Fellowes;

- Bedside commodes, shower chair benches, grab rails, wheelchairs, and bath safety equipment by Medline;

- Hospital beds by Favero;

- Healthcare footwear by Watts; and

- Unified communications devices by Poly

While good cleaning and disinfection protocols are the critical first line defense, they remain only one element of an ideal approach. A complementary option for providing the best healthcare environment is through the utilization of built-in antimicrobial protection that is always working and is durable for the life of the product.

Microban has a wide range of antimicrobial solutions for all types of touchscreens and cell phone / tablet cases. Our solutions are available directly to manufacturers of touchscreens and other products used in the healthcare industry. These solutions include high durability coatings designed specifically for touchscreens as well as smart masterbatch solutions for resin components. There isn’t a surface that we can’t treat!

Completing the 3-step approach to a best-in-class healthcare environment, Microban has partnered with one of the leading providers of disinfection and sanitization solutions to the healthcare sector, in order to provide advantaged disinfection products that are powered by Microban technology. Professional Disposables International (PDI) offers Sani-24 germicidal spray - the world’s first continuously active disinfectant which provides around the clock protection. Powered by Microban, it is the first, and only EPA-registered disinfectant with the ability to control HAI-causing microorganisms with Continuously Active Disinfection for up to 24 hours.

Conclusion

While the use of electronic devices in healthcare environments has become necessary to efficient patient care, the need to maintain the cleanliness and hygiene of these devices should not be overlooked. Regular and thorough cleaning routines combined with the utilization of products with built-in antimicrobial technology can help to address infection control issues, and minimize the risk of cross-contamination.

Microban technology has a long history of safe use in healthcare environments. Not only do the unique formulations remain present and active in a treated surface for its expected lifetime, but they also provide around-the-clock product protection in between cleanings.

To discover how Microban antimicrobial technology can benefit your healthcare sector products, contact a member of the Microban team today.