Environmental antimicrobial coating innovations

As environmental and health concerns continue to grow, the need for alternative and sustainable solutions has kick-started in the development of more favorable toxicity profiles.

This has sparked innovation towards integrating non-heavy-metal and metal-free antimicrobial formulations into coatings such as Ascera and LapisShield.

How do antimicrobial treatments work for coatings?

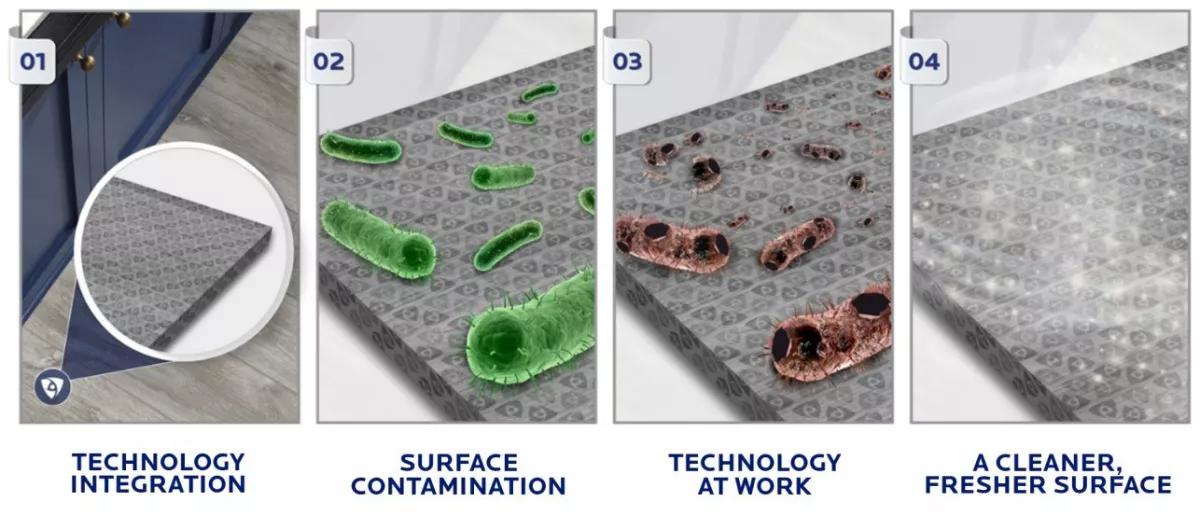

Antimicrobial treatment works by incorporating active agents into the coating material that prevent the growth and spread of bacteria, mold, and mildew. These agents can be applied to a wide range of coatings, including water-based, solvent-based, high solids, and powder coatings.

Once treated, the antimicrobial agents work by disrupting the metabolic processes of microbes, preventing them from reproducing. As a result, the coatings protect surfaces, helping them stay cleaner and for longer, reducing the need for frequent cleaning and maintenance and enhancing durability.

Latest coating industry trends

The coatings industry is rapidly evolving to meet the increasing demand for sustainable and long-lasting coatings. As governments and consumers alike prioritize environmental sustainability, the push for innovation in the industry will continue to revolve around four themes centered on functionality:

Durability

Consumers today expect durable products that retain their quality for a longer period of time, driving the demand for more robust coating solutions and influencing technology developments.

The durability of the coating largely depends on the application and environmental conditions under which it must perform. For example, exterior coating applications may be susceptible to weathering and corrosion. Sunlight, heat, and moisture can cause blistering, swelling, and cracking, leading to deterioration of the coating's surface over time. As a result, durability for exterior coating applications is often determined by color and gloss retention as well as resistance to weathering.

Regulatory

Increasingly strict environmental regulations and growing consumer expectations for more sustainable products continue to create challenges for coatings manufacturers.

The question arises for manufacturers about how to replace chemicals that face regulatory challenges. In general, the market is seeking better health and wellness solutions as seen in China where regulations regulating a reduction in VOC emissions are driving a variety of changes.

Sustainability

The topic of sustainability continues to be a top priority amongst paints and coatings manufacturers, customers, and end-users.

In addition to reducing VOCs and the elimination of toxic ingredients to develop more sustainable coatings, energy and resource conservation, waste management, use of renewable materials, and length of service life are all elements for consideration.Antimicrobials

Antimicrobial coatings offer a long-term solution to combat the growth of degrading and harmful microbes. According to research, the global antimicrobial coatings market is expected to attain a value of USD 25.24 billion by 2030, with a CAGR of 13.9% during the forecast period (2023-2030).

This growth is attributed to the increasing demand for more durable products and the need for better surface cleanliness measures in various industries, including healthcare and food packaging.

Sustainable innovations in paint technology

With rising demands for quality and performance, here are the industry trends and innovations in paint technology to watch:

Improved indoor air quality and odor-elimination

Improving indoor air quality is a major consideration amongst building professionals and building occupants, most notably in the education and healthcare sector. There are many pollutants in the air - including volatile organic compounds (VOC) and formaldehyde - which are naturally emitted from paint, varnishes, furniture, carpets, cleaning products, and other building materials.

As a result, Building Regulations and Governments are increasing encouragement to achieve healthy indoor environments through building and equipment specification to internal finishes, paving way for low-VOC paint. This is a form of paint that contains fewer VOC or VOC solvents than traditional coatings.

- Enhanced resistance to mold and mildew on the surface

Moisture and humidity create a breeding ground for mold and mildew to thrive, commonly seen in bathrooms, wet rooms, and kitchens. In response, consumers are demanding more durable products with high performance against mold and bacterial growth.

This is where mold-resistant paint comes in. Designed with antimicrobial technology, the paint inhibits the growth of mold and mildew on painted surfaces. The built-in formulation works 24/7 for the expected lifetime of the product, helping the surface paint to stay hygienically cleaner, fresher, and more durable.

The importance of antimicrobial paints & coatings

Antimicrobial coatings have become increasingly popular in recent years due to their ability to combat microbial attack, which can cause significant damage and deterioration to coatings, ultimately resulting in costly maintenance, replacement, and premature disposal.

To address this issue, coatings with antimicrobial properties are now in high demand, particularly in high-traffic areas such as hospitals, schools, and public spaces where maintaining a clean environment is crucial. By integrating antimicrobial coatings, the end result is a product that stays cleaner and fresher for longer, in-between cleanings. This reduces the need for resource intensive maintenance and replacements, lowering the carbon footprint associated with the coating process and minimizing the use of harsh cleaning chemicals that can be harmful to the environment.

Common product applications for antimicrobial coatings include medical devices & equipment, touchscreen kiosks, electronic devices, transportation, building & construction materials, and HVAC systems

How to make your paints & coatings more sustainable

There are multiple approaches that exist to create more sustainable coatings formulations and extend the product life of the coating.

Protect against UV radiation: UV radiation from the sun can cause damage to coating materials, resulting in issues like discoloration, cracking, and peeling. Coatings with UV protection block or absorb UV radiation, preventing it from penetrating the surface and causing damage. Some coatings contain UV-absorbing particles, while others have a built-in UV barrier for extra protection.

Improve resistance UV radiation: UV stabilizers are chemical additives that can be added to coating materials to increase their resistance to UV radiation. By absorbing or reflecting UV radiation, the stabilizers help prevent the breakdown of the coating material and extend its lifespan.

Slip and abrasion resistance: Slip-resistant coatings can prevent slip and fall accidents, particularly important in areas where the floor or surface is likely to get wet or oily, such as kitchens, bathrooms, and industrial settings. On the other hand, abrasion-resistant coatings withstand wear and tear, requiring less maintenance and replacement, and reducing waste.

Surface treatment: This is an essential step in preparing a substrate for coating, and it can have a significant impact on the durability of the coating products. By improving adhesion, durability, performance, and appearance, surface treatment can help to ensure that coatings remain effective and functional over an extended period of time.

Antimicrobial protection: Antimicrobial coatings contain active agents that prevent the growth and spread of bacteria, mold, and mildew on surfaces. This reduces the need for frequent maintenance, replacement, and reapplication, ultimately reducing waste and environmental impact. Antimicrobial coatings also promote a cleaner environment, which is crucial in high-traffic areas like hospitals and public spaces. By staying cleaner for longer, these coatings reduce the need for harsh cleaning chemicals that can harm the environment and end up in waterways.

These approaches can help manufacturers create more sustainable paints and coatings that will last longer and provide long-term benefits for your business and the environment.

Contact Us For More Information

As the industry leader in antimicrobial solutions, Microban technologies can be seamlessly integrated into a range of coating applications without disrupting the desired look, feel, or functionality. Contact a member of the Microban team today for more information.

Watch the video below to hear from Microban’s in-house coating expert, James Rapley, on the journey to identifying the right antimicrobial coating solution.