The truth about mold growth on building materials

Mold growth in buildings continues to be a major issue facing the construction industry, property managers and homeowners. Whilst gradual in nature, mold, mildew and algae can cause severe structural damage and pose human health risks over time if not addressed properly.

Take a look at these harrowing figures relating to mold growth:

Over half of reported snagging issues for new build homes in the UK were related to visible signs of mold growth (AYTM 2022).

82% of new-build homeowners in the UK are concerned about mold growth (AYTM, 2022).

The most serious hazards in privately rented homes in the UK, including mold, are estimated to cost the NHS £340 million a year.

There was £1,750 compensation for a UK tenant where leaking gutters contributed to black mold in the property.

According to fixr, the national average cost in the US to remove mold professionally is between $1,500-$9,000.

PVC and mold: a dangerous duo

Polyvinyl chloride, also known as vinyl or PVC for short, is one of the most widely used plastics in the world. In Europe, 70% of PVC produced is used in building applications, often replacing traditional building materials such as wood and concrete due to its versatility, durability and lightweight attributes.

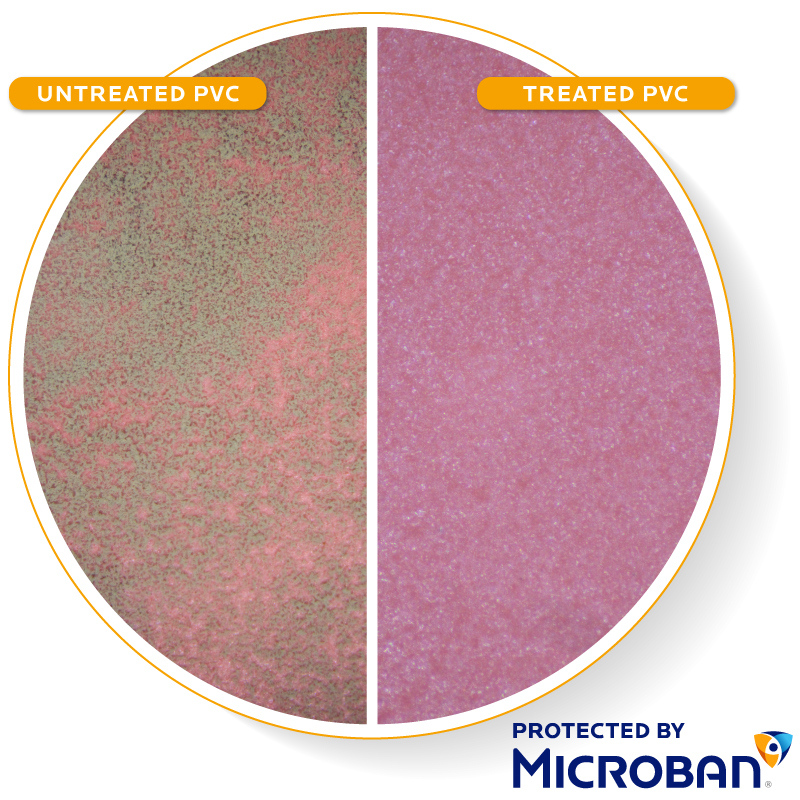

PVC building materials contain plasticizers to enhance their flexibility It is these plasticizers that contribute to degrading mold growth, resulting in material discoloration, odor, and diminished performance over time.

The best line of defense against mold and fungi is prevention. Building material manufacturers should consider longer-term solutions to enhance product durability, such as incorporating built-in antimicrobial technologies into the material during manufacture.

What types of PVC products are susceptible to mold growth?

Take a look at the types of PVC building materials prone to mold, mildew, and algae attacks, and how Microban antimicrobial technology can help.

Plastic pipes

PVC piping applications are extensively used around the world for safe drinking water and sewage systems. However, the challenge for manufacturers is biofilm formation. The reality is, changes in temperature, pressure, and flow rates, as well as the source of the water, all affect pipe cleanliness.

An example of this was at the start of the COVID-19 pandemic which saw multiple cases of microbial contamination and biofilm development in dormant piping systems. The accumulation of nasty microbes in pipework is not only a product-hygiene concern but also a threat to its performance and durability.

Built-in antimicrobial product protection offers an added layer of defense for plastic piping. Integrated at the stage of manufacture, antimicrobial technology works to prevent microbial accumulation in the piping system, helping to minimize foul odors, reduce the risk of blockages, and extend its useful lifetime.

PVC roofing membranes and corrugated sheets

While the principle of a roofing membrane is to protect a building against mother nature, its large surface area exposes them to variable elements and temperature changes. This can lead to damaging mold and algae growth, affecting both the aesthetics and performance of the roofing over time. If left unaddressed, mold can cause severe structural damage to a building, resulting in high maintenance costs and even decreasing property value.

PVC roof sheeting commonly found on outbuildings, garden sheds, and extensions also faces the risk of microbial attack due to their outdoor exposure.

Roofing materials enhanced with built-in antimicrobial technologies actively resist mold growth 24/7. This intrinsic product protection helps to extend material longevity, preserve aesthetics and support more sustainable buildings.

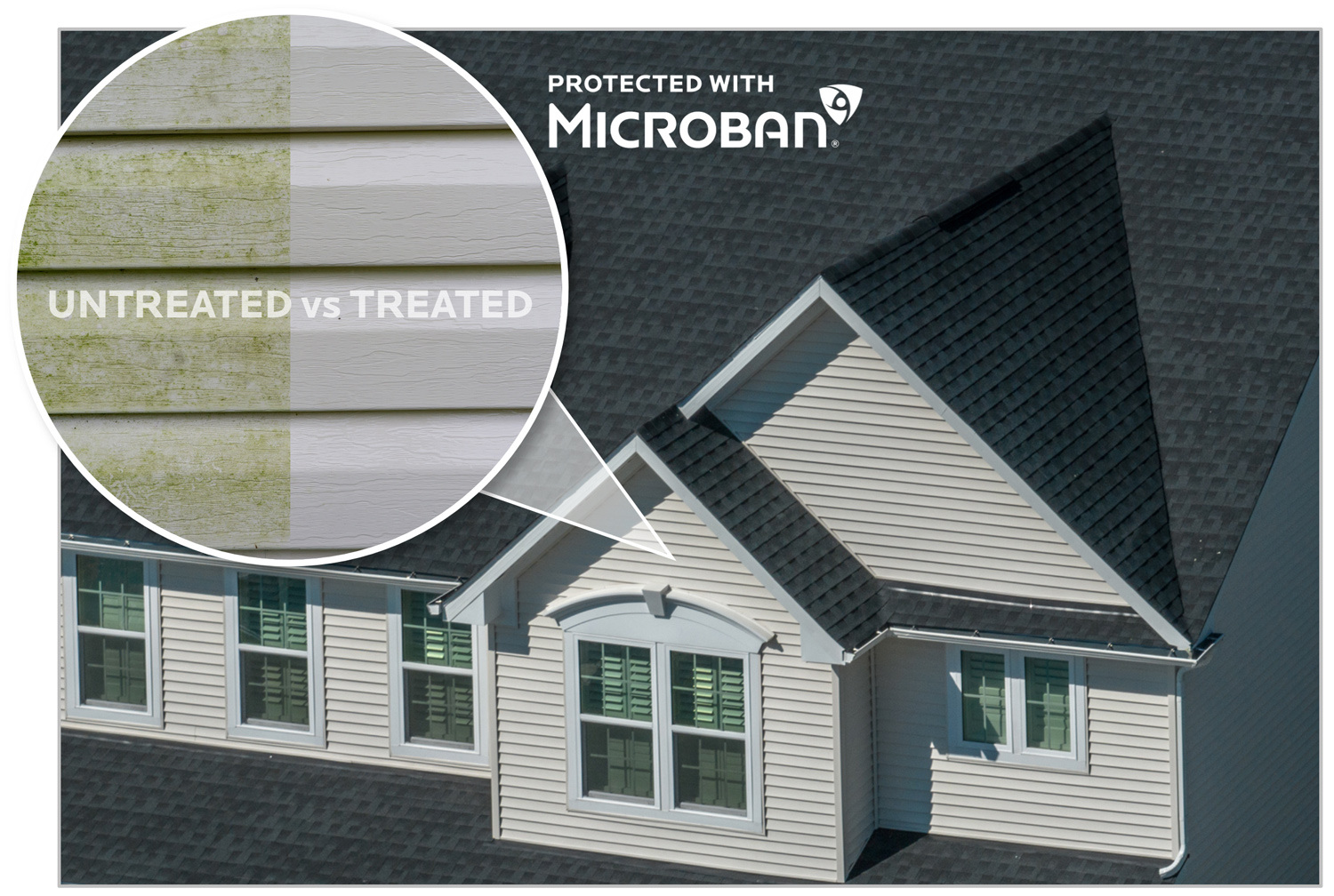

PVC siding

The durability and affordability of PVC siding make it a popular choice and cladding solution for homes and buildings, particularly in the USA and Canada. However, the downside to this material is its susceptibility to mold and mildew growth.

Externally wrapped around a building, the siding can accumulate a host of dirt, grime and other pollutants caused by animal droppings, human traffic and variable climatic conditions. This presents the perfect environment for mold and mildew to thrive, often leading to early material degradation and diminished aesthetics.

PVC siding treated with built-in antimicrobial protection benefits from enhanced longevity and cleanliness by resisting microbial growth 24/7/365. Proven by science, antimicrobial technology delivers an ‘always-on’ line of defense, working to complement regular cleaning and maintenance.

Vinyl flooring

Vinyl is a common flooring choice in homes and commercial buildings. It’s easy to maintain, cheap to install, and more durable than other flooring types. However, vinyl is still prone to microbial attack.

A favorite for high-traffic areas, vinyl flooring is exposed to foot traffic, spillages and cleaning lapses. These can all contribute to degrading bacterial growth on the surface, which manifests in the form of discoloration, stains, swelling and peeling. The grooves, edges, and unsealed seams of vinyl flooring also mean water can get trapped underneath it, leading to damaging mold growth.

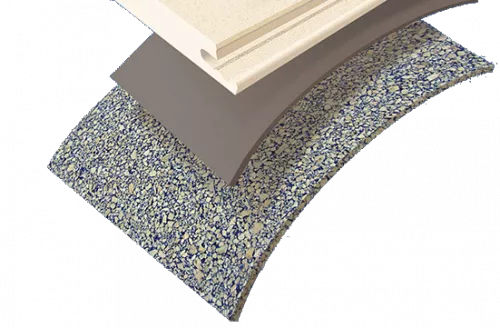

Vinyl flooring treated with built-in Microban antimicrobial technologies benefits from continuous, long-lasting surface protection against degrading microbes. Integrated into the wear layer during manufacture, Microban technology works to preserve the quality, design, and finish of the flooring. Microban protection can also be added to flooring underlay, helping to prevent damaging mold growth.

Flooring manufacturers that work with Microban

Mannington Mills: Antimicrobial Luxury Vinyl Tile and Sheet Vinyl

Mannington Mills LVT and sheet vinyl products are manufactured with built-in Microban technology, providing permanent surface against protection from the growth of bacteria, mold and mildew.

Torlys: Antimicrobial Underlay for Flooring

TORLYS™ Smart Core with Microban keeps floors cleaner, ensuring the core remains clean and fresh even if bacteria were to reach it. On the bottom, CorkPlus™ Blue & FoamPlus™ Blue underlays with Microban help prevent mold and mildew growth under the floor.

Awnings

Wet weather can have a profound impact on outdoor furniture and screens, such as awnings. Consistent moisture will soak into the material which can lead to unsightly mold and mildew growth. Regular cleaning can help to some extent, but will not remove the root of the problem. Unfortunately, fabrics that have become infested are very hard to save; the microbes will create stains, making your furniture and screens slimy and smelly. In addition, mold and mildew can even dissolve the weave, creating weak spots that rip more easily, shortening the lifetime of the product.

Awnings enhanced with built-in antimicrobial technologies benefit from 24/7/365 surface protection against stains, odors and premature degradation caused by microbial build-up. This means the product will stay cleaner and last longer, helping complement regular cleaning routines and keeping your outdoor space looking great, even when the weather isn’t.

Futureproofing PVC building materials against mold and algae

Historically, arsenic-based biocides have been used to confront fungal growth in PVC building applications. However, global regulatory changes are driving a reduction in concentrated levels of these additives, forcing manufacturers to look for oxybisphenox-arsine (OBPA) alternatives.

MicroGuard™: proven antifungal protection for PVC

MicroGuard is a unique line of non-leaching, metal-free antifungal additives from Microban International.

Representing an alternative to OBPA, MicroGuard can be built-in to PVC building materials at the point of manufacture to deliver 24/7 antifungal product protection. MicroGuard technology remains active for the lifetime of the material - even in the harshest of environments - and will not wash off or wear away.

Key benefits of integrating Microban antimicrobial protection into your PVC building materials:

Lifetime protection against the growth of stain and odor-causing bacteria, mold and mildew

Enhanced product durability and performance

Extended product lifetime, supporting sustainability initiatives

Helps products stay hygienically cleaner in-between cleaning and makes them easier to clean

Technology does not wash off or wear away, remaining active 24/7 for the useful lifetime of the product

Delivers added peace of mind in both homes and commercial spaces