What is the current size of the global antimicrobial additives market?

The COVID-19 pandemic and consumer concerns over cleanliness are driving demand for antimicrobial technologies across markets. According to Allied Market Research (AMR), the global antimicrobial additives market forecast was valued at $4.7 billion in 2020 and is projected to reach $9.3 billion by 2030, registering a CAGR of 7.1% from 2021 to 2030.

How is the antimicrobial additives market predicted to grow?

Plastics Industry

Globally, the plastic segment dominated the market in 2020 and is predicted by AMR to increase by 7.3% over the forecast period. Antimicrobial additives integrated into plastic and polymer products can inhibit the growth of stain and odor-causing bacteria, resulting in longer-lasting products.

Building materials made from plastics are particularly vulnerable to degradation and discoloration caused by microbial growth, with additional support from climatic conditions. Examples include pipes, insulation, flooring, roof systems, and fixtures and fittings. This can impact the longevity of a building, resulting in costly maintenance and repair work. The integration of antimicrobial technology into building products results in more durable and cost-effective construction projects that stand the test of time.

With a growing need for sustainable products, promoting less waste, and reducing environmental impact, the antimicrobial additives market for plastics shows steady growth with no signs of slowing down.

Coatings

The demand for antimicrobial coatings can be attributed to the growing awareness of cleanliness and hygiene alongside stringent regulations. According to Markets and Markets 2020, the global market is projected to reach USD 6 billion by 2026 and grow at a CAGR of 10.5% during the forecast period.

Sector-specific, antimicrobial coatings have seen exponential growth in the medical and healthcare industry as an action to prevent cross-contamination. Crowded healthcare facilities, combined with the constant movement of staff, patients, and visitors all contribute to microbial transfer, which can also reach objects and surfaces through frequent handling and cleaning lapses.

In healthcare, antimicrobial coatings are commonly found in medical devices and equipment including medical textiles (e.g. shower curtains, privacy curtains, staff uniforms, and footwear) and reusable equipment (e.g. medical touchscreen devices and grab rails). The integration of antimicrobial coatings helps to reduce the risk of microbial cross-contamination from surface to surface.

In support of this, Asia Pacific is expected to witness high growth in the near future as a result of increased production of medical devices in China, Japan, and India.

Packaging

Antimicrobial packaging is expected to register a CAGR of 5.89% from 2021 to 2026.

Antimicrobial packaging, such as packaging films and food-storage containers, is designed to prevent the growth of bacteria, mold, and mildew, keeping products fresher and cleaner for longer.

With increased concern for the environment and public awareness, the majority of industries have been looking to reduce the use of single-use plastic packaging. Food packaging in particular is a growing concern, because of the large amount of waste produced and potential health risks posed by chemical leaches. Examples include plastic bottles, disposable cups, lids, and straws. According to research by Trivium Packaging, 74% of consumers said they would pay more for sustainable packaging and nearly half would shy away from packaging that could harm the environment.

While recycling can help reduce packaging's environmental impact, it can't eliminate it alone. Much of this has meant that retailers and manufacturers have had to adapt and incorporate smarter packaging design.

New packaging trends are emerging to attract a new generation of consumers factoring environmental impact and added peace of mind into their purchasing decisions. Antimicrobial packaging helps to provide inherently cleaner alternatives. Integrated into packaging materials at the stage of manufacture, antimicrobial technology provides cleaner, fresher, and more durable packaging, contributing to decreased cleanliness anxieties and a more circular economy.

Why are more companies investing in antimicrobial technology?

48% of people have increased anxiety around dirt and cleanliness since the start of Covid-19. This has prompted an increase in companies using antimicrobial additives to create cleaner products in response to consumer concerns over product cleanliness and hygiene.

Contrary to standard disinfectant sprays, which work for a limited period of time, antimicrobial technology is built-in to products during manufacture and remains active for the life of the product without risk of being washed off or worn out. The result is a surface or product stays cleaner and lasts longer, delivering added peace of mind for consumers.

In addition to cleanliness concerns, the topic of product sustainability continues to grow as part of a global environmental challenge to care for the planet. According to the Economist Intelligence Unit (EIU), there has been a 71% global rise in online searches for sustainable goods over the past five years. Additionally, Accenture researchers found that 72% of respondents were actively buying more environmentally friendly products at this time than they were five years ago, while 81% expect to buy even more in the next five years. Among the respondents, 83% believe it’s important or extremely important for companies to design products that are meant to be reused or recycled.

In support of this, built-in antimicrobial additives can enhance product durability by inhibiting the growth of bacteria, mold, and mildew that causes material degradation and ultimately premature disposal. By preventing microbial contamination on the surface, manufacturers can extend the lifespan of products which in turn, encourages reusability and reduces the risk of them ending up in landfills.

How can Microban's antimicrobial technologies help your product reach new markets?

As the world moves on from the pandemic, purchasing habits are likely to be characterized by the demand for smarter products that are longer-lasting and environmentally friendly. Utilizing Microban technologies could facilitate increased consumer preference and a higher price point (Multi-sponsor Surveys, 2020).

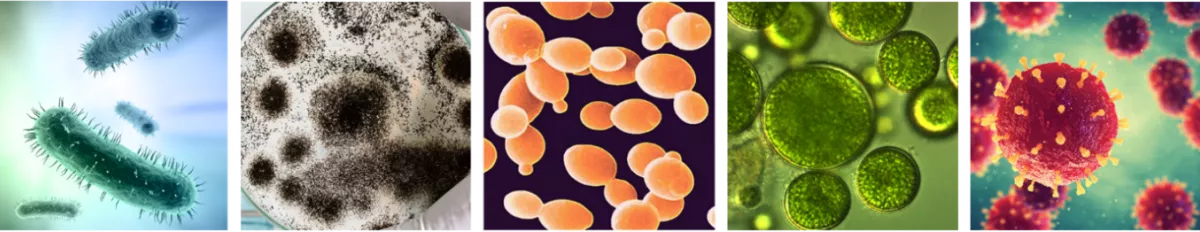

Leading the industry in odor-control and antimicrobial additives, Microban® technologies offer proven performance against a variety of microbes for a range of product applications, without compromising on quality and performance.

Microban antimicrobial technologies offer many benefits, including:

- Help keep your products cleaner and fresher for longer, in-between cleans

- Extend the usable lifespan of products

- Help reduce the growth of bacteria, mold, mildew

- Reduce the risk of microbial cross-contamination from surface to surface

- Safe for use in a variety of environments including healthcare and hospitality

- BPR notified, EPA registered and approved for use in food-contact applications

- Help brands and manufacturers gain a competitive advantage

- Deliver added peace of mind to consumers

Conclusion

In general, the antimicrobial additive market has seen high demand in recent years due to increased attention on hygiene and product cleanliness catalyzed by COVID-19. As consumer attitudes continue to evolve, cleaner, more durable products continue to rise in perceived value, thereby driving the industry’s growth.

In order to gain a competitive edge and tap into potential opportunities, brands and manufacturers should consider incorporating antimicrobial additives into their product lines.

Contact a member of the Microban team today for more information.