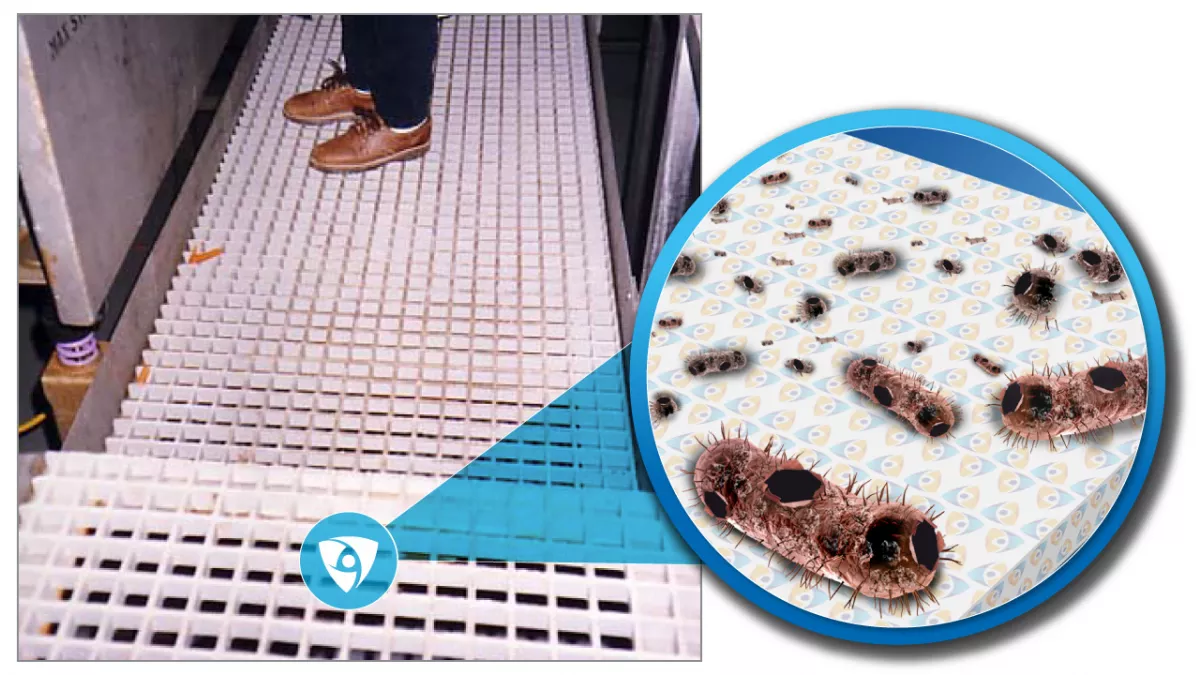

Antimicrobial FRP grating products from Fibergrate and Microban

In 1966, William C. Coonrod invented fiberglass molded grating in his Dallas, Texas, garage. That first panel was the beginning of Fibergrate. They are now an international company with a presence in 11 countries, and their customers have installed Fibergrate products on projects in more than 40 countries on 7 continents.

Why Add Antimicrobial Technology to Fibergrate® FRP Resins?

Despite their apparently smooth finishes, most FRP products have micropores on the surface that allow bacteria and fungi to survive. This can lead to the development of odors, discoloration, and mildew. Microban® has been successfully proven to inhibit the growth of common microbes on the surface of composite products.

- The benefits of incorporating this antimicrobial technology into Fibergrate’s products can include:

- Reducing the overall microbial load on surfaces

- Reducing lingering odors and the risk of staining

- Protecting against corrosion or degradation caused by microbes on the FRP material

- Partnering with the most recognized antimicrobial brand in the industry

Key Industries That Can Benefit From Fibergrate® with Microban®

Steve Ludwig, Fibergrate’s Vice President of Marketing and Product Development, shared his view on the impact for structural and safety engineers seeking to support workplace health and safety. “We work with many businesses in the food and beverage industry where keeping surfaces clean can be challenging with so much organic material in the work environment. We hope that including a leading antimicrobial solution like Microban® across a range of Fibergrate® FRP products will help our customers maintain their cleanliness standards more easily. We also expect to see adoption in the water/wastewater sector.”

Building the World to Last® With Protection That Lives On™

The combination of ongoing antimicrobial protection and durable products is a good match for challenging environments where frequent cleaning is non-negotiable. As with any flooring system, FRP gratings must always be maintained using proper sanitation and hygiene practices, even if they include antimicrobial technology. While Microban® can help to inhibit the growth of damaging bacteria on FRP products, it does not protect users or others against food-borne (or disease-causing) bacteria and is intended only for non-public health uses.

Fortunately, Fibergrate’s durable products are easily cleaned with a high-pressure washer and are resistant to chemical interactions with common cleaning and sanitizing agents. The integrated Microban® technology is expected to remain effective at reducing the bio-burden for the product’s lifetime. It will not wash off, leach out, or wear away. This makes it an ideal match for Fibergrate’s long-lasting FRP products.