In many organisations, plastic has proven a reliable and inexpensive friend helping to advance product innovations. From the luxurious Airbus A380 to the standard toothbrush - all while keeping costs low and offering consumers ample choice across market sectors.

In spite of plastic's poor reputation, especially among the eco-conscious consumer, there are plenty of sound reasons for its widespread use. Lightweight, affordable, durable, and extremely versatile, plastic has a lot to offer.

Aerospace and rail manufacturers, as well as auto manufacturers, frequently employ plastic due to its lightweight properties and ability to save fuel in the long run as a result. Swiss trains, for example, reduced their weight by 25% by using composite panels made of plastic.

According to research by the British Plastics Federation, opting for plastic pipes in the building industry is a more sustainable choice than using concrete or steel pipes since it requires less energy to produce. The replacement of Victorian pipes in London with plastic pipes was reported to contribute to significant water and energy savings across the city through the reduction of leakages and pumping of water.

However, plastic products today are notoriously hard to recycle and their impact on our planet is making for pretty harrowing headlines. This is prompting governments, businesses, and even consumers to take meaningful actions in the war on plastic pollution.

Antimicrobial Plastics: Putting The Customer (and the Environment) First

Addressing Cleanliness Anxieties

Anxiety and hygiene have been hot topics over the last two years with a rising focus on cleanliness and disinfection. One reason: the pandemic. 48% of people have increased anxiety around dirt and cleanliness.

Protecting plastic products from microbes allows brands to appease cleanliness anxieties and deliver added peace of mind for consumers.

Reducing Food Packaging Waste

In the food and beverage sector, plastic plays a critical role in the preservation of food items. Plastic packaging helps prevent cross-contamination issues, thereby reducing food waste and greenhouse gases released from the decay of food in landfill - 25 times more harmful than carbon dioxide in terms of trapping heat into the atmosphere. Zero Waste Scotland found that the carbon footprint of food waste collected from Scottish households in 2016 alone was almost three times higher than that of plastic waste.

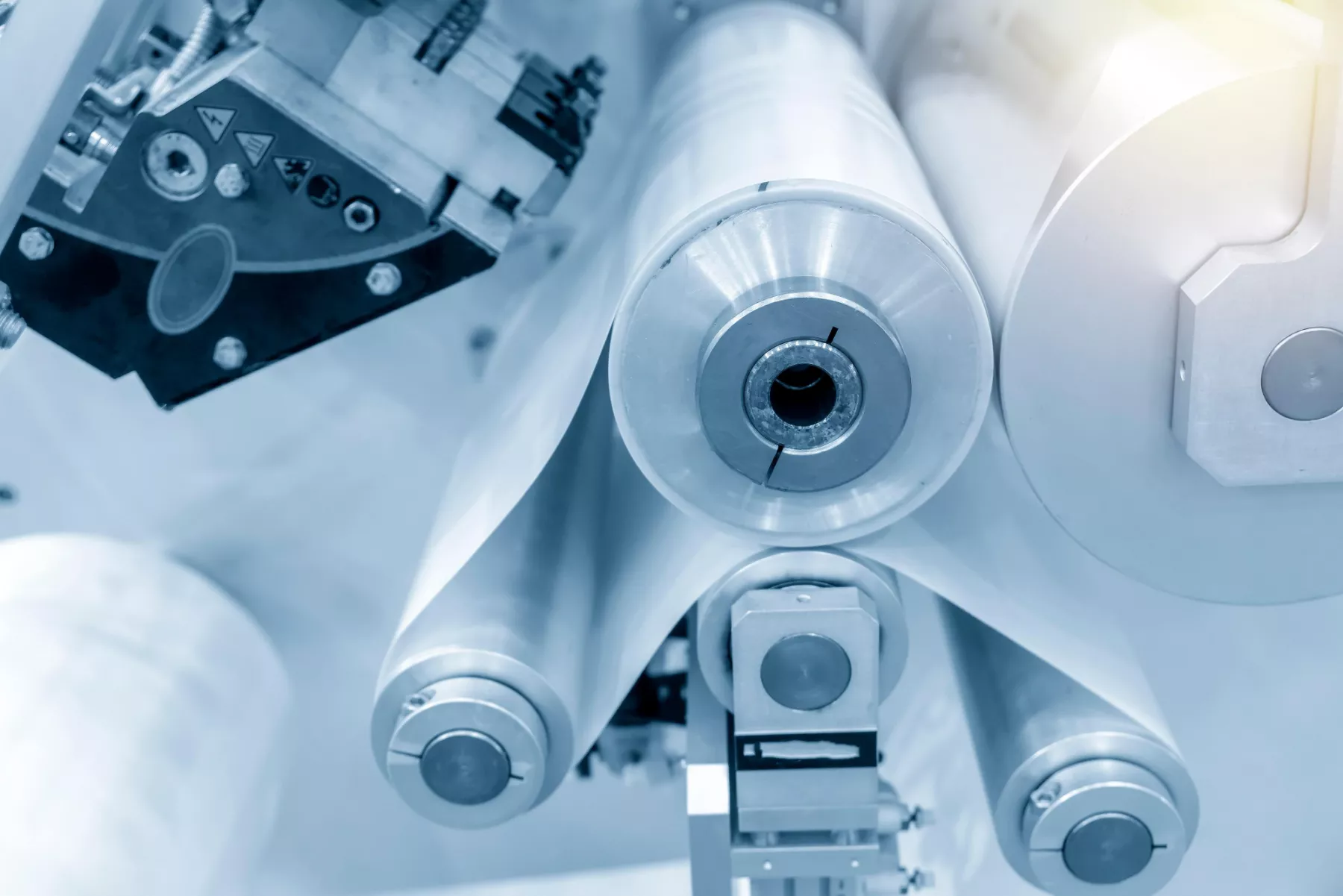

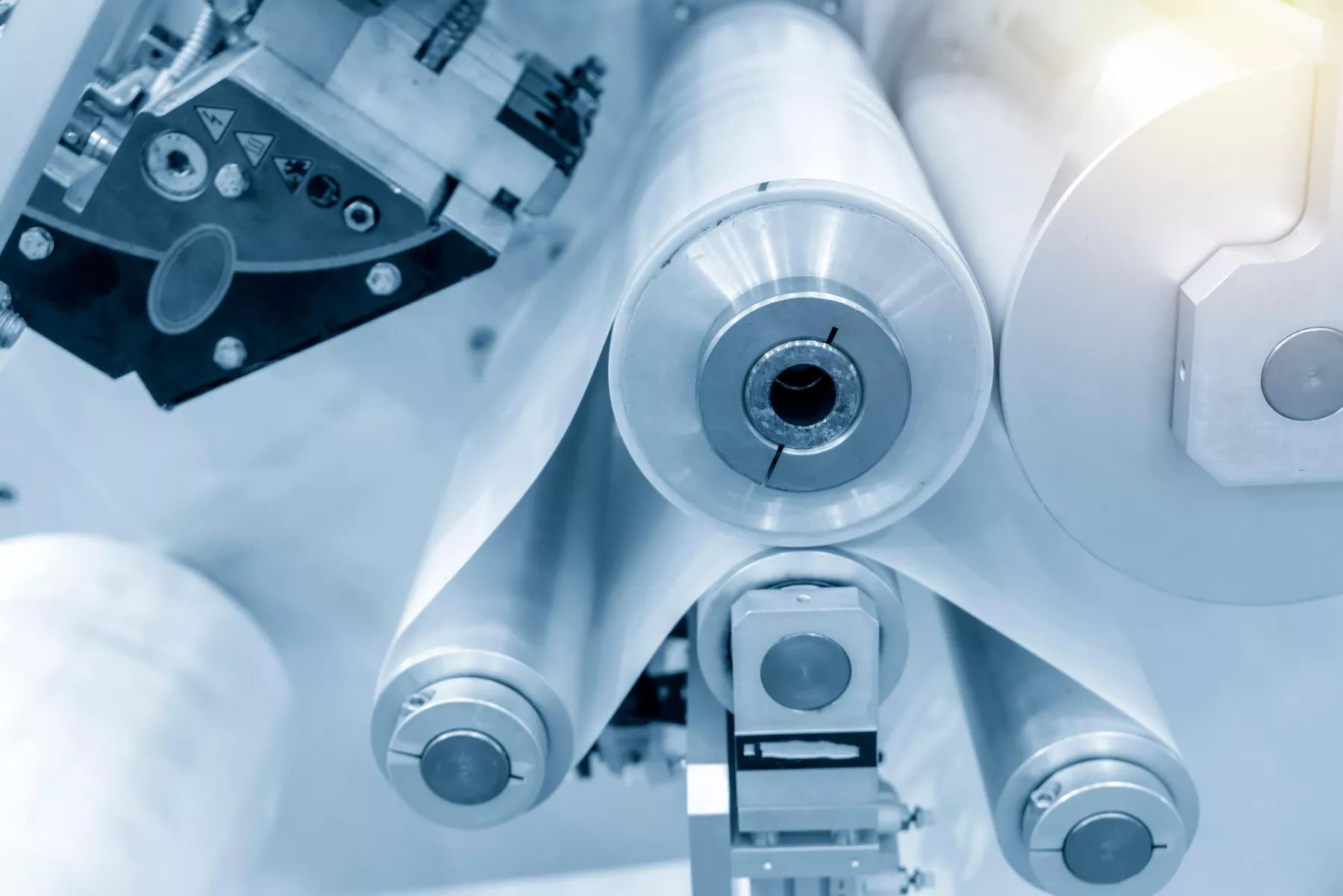

With a growing global population and no sign of mass food production slowing down, the journey from farm to table is becoming increasingly complicated. Without food-grade plastic packaging and films, we lose the ability to transport food from place to place or cook using foreign produce and seasonal items.

On the other hand, as food engineer Vanessa Grondin rightly pointed out, where we gained in practicality and food security, we lost in our capacity to manage waste materials and our environmental footprint. Truth is, disposal of food packaging is almost unavoidable.

Or is it?

Manufacturing smarter food packaging that is crafted for reuse could well be the answer to reducing food packaging waste. Integrating built-in antimicrobial technology into the plastic materials not only helps reduce bacteria, mould and mildew growth, but also maintains the visible cleanliness and durability of the packaging. This means consumers are more encouraged to reuse vs. replace.

Watch the video below to see the differences in mould growth in an untreated food container vs. an antimicrobial food container.

Supporting a Circular Economy

An estimated 11 million metric tons of plastic waste enters the ocean every year. For decades, efforts to reduce plastic pollution have focused on reducing single-use plastic and improving recyclability as part of sustainability policies and government commitments towards climate action.

Enhancing product reusability and durability is a further approach manufacturers can adopt to effect change.

Now, with frequent use and everyday life comes microbes. Bacteria can double in number every 20 minutes on standard product surfaces, even after proper cleaning. This often results in premature product degradation and ultimately disposal. By preventing microbial contamination on the surface of plastics, you can extend the lifespan of your products.

Expand Reuse with Antimicrobial Plastic

Plastics enhanced with antimicrobial technologies offer an added layer of product protection against microbial growth that remains active for the product’s expected lifetime. The ability to seamlessly integrate into a wide range of plastic materials, including colour masterbatches and polymers, means a whole host of products can benefit from increased shelf-life, enhanced cleanliness and prolonged freshness.