During this global pandemic, the market for disposable gloves has reached an all-time high and polyethylene gloves are projected as one of the most lucrative segments. Unfortunately, it’s not uncommon to see those baby blue and white gloves everywhere you go these days. But you may be wondering, how well do these gloves actually protect against germs and viruses? What’s more, is there a way to protect the single use gloves themselves from the growth of microbes?

What Are Disposable Gloves?

Disposable gloves are hand coverings that you wear once and then throw away. They are primarily employed in hygiene-conscious settings to protect users and help prevent cross-contamination. These gloves can be made of different polymers including latex, nitrile, rubber, polyvinyl chloride, and neoprene.

Latex gloves are made from natural rubber. They are considered to be the most comfortable and tactile for use in detail-oriented practices such as surgery and tattooing. Despite the advantages of latex gloves, they have become an issue for many due to the high rate of latex allergies. In fact, many occupations choose to use non-latex glove options such as nitrile and vinyl gloves instead.

Medical gloves can come unpowdered or powdered with cornstarch to make them easier to wear. Powder free disposable gloves are often used for medical examinations and work to help prevent the spread of hospital-acquired infections (HAIs).

Vinyl gloves made from PVC tend to be the cheapest latex-free glove option, but many prefer to use more durable options such as nitrile gloves. Nitrile gloves tend to replicate the stretchy feel of latex gloves but are latex-free, durable, and puncture resistant.

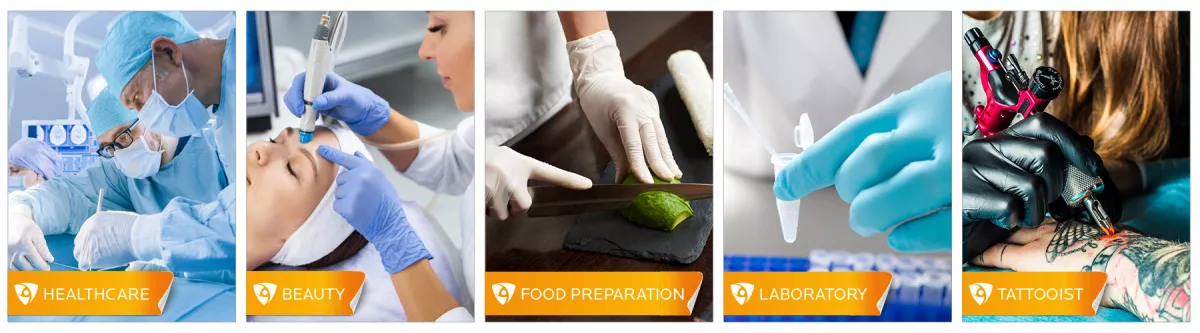

Disposable gloves should be worn to protect the wearer from the hazards of the job they occupy. Many professions require contact with elements that are breeding grounds for microorganisms and/or involve exposure to harsh chemicals. These occupations include healthcare workers, surgeons, tattooists, food service workers, automotive technicians, gardeners, chefs, nail technicians, housekeepers, painters, janitorial staff, plumbers, cafeteria workers, scientists, animal protection workers, and even childcare workers.

Why Are Disposable Gloves Important?

Disposable safety gloves create a protective barrier around your hands. They can help prevent infection from bodily fluids and viruses, burns from harmful chemicals, and wear and tear from the elements. As well as helping to minimize the risk of cross-contamination, rubber gloves also work to protect products and surfaces from contamination by soiled hands. For these reasons, it is important to use the correct gloves in a safe and effective manner.

It’s important to note that while gloves play an important role in infection control, they should not replace regular handwashing and normal hygiene practices.

How Could Disposable Gloves Benefit From Built-In Antimicrobial Technology?

Clinical studies show that medical gloves play a key role in preventing the transmission of pathogens in healthcare and food service industries. However, the gloves themselves can still facilitate the growth of harmful microorganisms, leading to unwanted cross-contamination.

Currently, it is estimated that 48 million people become sick each year in the United States due to the cross-contamination of food borne illnesses by disposable gloves. And, across the US and EU, over 5 million people are affected by healthcare associated infections caused by contaminated gloves. This affect prolongs hospital stays, increases medical costs, and fuels unnecessary suffering.

Surprisingly, bacterial contamination can even begin during the manufacturing of the gloves. Studies have shown that environmental bacteria were present on most glove samples taken directly from the manufacturing line. Since single use gloves are non-sterile, there is a possibility of microbial growth even after packaging.

Built-in antimicrobial technology provides an active layer of defense against microbes by continuously inhibiting their growth on the surface of the gloves.

Working at a cellular level, the technology disrupts the vital life processes and biological functions of contaminating microbes. As a result, they cannot grow or reproduce on the surface of the treated glove and subsequently die. This proactive product protection keeps the gloves cleaner before, during and after use. What’s more, the antimicrobial properties operate 24/7 and will not wash off or wear away.

How Can Microban® Technology Be Applied to Disposable Gloves?

General purpose disposable gloves are typically manufactured by dipping a mold into a desired liquid polymer, natural rubber, or nitrile solution. In this case, Microban® antimicrobial technology would be incorporated into the liquid by mixing a pre-existing liquid additive to the glove solution. Once the mold is dipped into this solution, the antimicrobial rubber will form around the mold creating antimicrobial gloves.

Determining which Microban® additive to use depends on certain regulatory restrictions and the intended use of the gloves. For example, if the gloves were to be used in a medical setting, the manufacturer must get approval to use antimicrobial product protection through the FDA.

Incorporating built-in Microban® technology into disposable gloves offers a long list of benefits. Not only will the technology inhibit microbial growth on the surface of the product, but it will also help to address potential contamination issues during the manufacturing process. In addition to product advantages, offering smarter disposable gloves will deliver added peace of mind for users who operate in hygiene-critical environments.

Antimicrobial disposable gloves may not be the answer to everything, but they will certainly offer a helping hand.

IMPORTANT!

Due to regulatory differences, the performance claims related to Microban® technologies that are referenced in this article may not be valid for use in all countries or regions. In some cases, legal regulations may restrict or prohibit the selection of available Microban® technologies, the field of application for which they are approved, and/or the permissible claims for finished goods containing Microban® technologies. For more information, view our official regulatory statement or contact us.

Microban® technologies are not designed to protect users or others from disease-causing microorganisms or viruses and are not a substitute for normal cleaning practices.

*Subject to the performance properties of the antimicrobial agent manufactured into your product. Treated product efficacy claims against specific microbes are dependent on the results of laboratory testing.