Is Zinc Antimicrobial?

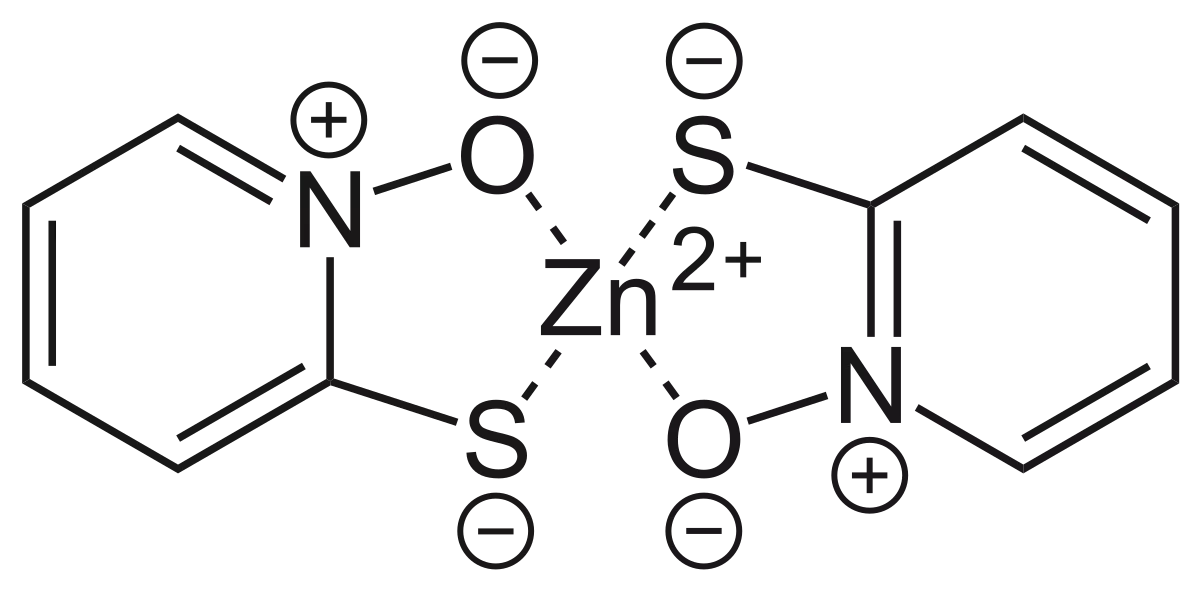

Put simply, yes, zinc does exhibit broad-spectrum antimicrobial properties effective against the growth of fungi as well as bacteria. Zinc pyrithione – a coordination complex of zinc – was first developed for its antifungal properties in the 1930s. However, it is still used today as a main ingredient in over-the-counter medications for a variety of conditions, as zinc is a Food and Drug Administration (FDA) approved treatment for fungal infections.

Beyond pharmaceutical applications, zinc is also registered with the FDA and US Environmental Protection Agency (EPA) as safe to use at low levels in a variety of products – such as paints, textiles, and polymers – to inhibit the growth of bacteria and fungi on susceptible surfaces and fabrics. For hard surface materials, these solutions are not designed to replace disinfectants, but to complement and extend the effectiveness of standard chemical cleaning routines. However, to know which everyday products can benefit from antifungal protection offered by zinc additives, it is necessary to understand how zinc works.

How Does Antimicrobial Zinc Work?

Mold and mildew begin as microscopic airborne spores, which germinate on contact with moist surfaces. These organisms can penetrate the surface, secreting enzymes to break down organic matter, then absorbing the newly digested nutrients that dissolve in water present in moist environments. However, zinc-based antifungal chemistries can penetrate fungal cell walls and disrupt key cellular functions to prevent the organism from functioning, growing, or reproducing. Zinc can do this via a few different generic modes of action:

- Increasing production of reactive oxygen species1, as well as decreasing and inhibiting cellular uptake of MnII, which plays a role in managing susceptibility to oxidative stress2

- Destabilizing microbial membranes on direct contact to the cell walls

- Raising cellular levels of copper, which damages iron-sulfur clusters in proteins essential for life3

What Type of Products Can Zinc Be Used With or Incorporated Into?

Numerous products we use on a day-to-day basis can be routinely exposed to moisture or humid environments – often without us even knowing. This provides perfect breeding grounds for fungi and bacteria. When left uncontrolled, these organisms can damage products – leading to staining, odors, and premature degradation, as well as potentially being harmful to human health.

Polyester-based materials are regularly used in textile production – for activewear, shower curtains, mattresses, pillows, shoe inserts, amongst many others – due to their durability, versatility, and stain and wrinkle resistance. However, they are at particular risk of damage and persistent unpleasant odors resulting from fungal growth if items are regularly exposed to moist environments and warm temperatures. These products are ideal targets for zinc-based antifungal treatments because bleach, ammonia, and other chemical disinfectants used to kill bacteria and fungi during cleaning can often damage or discolor them.

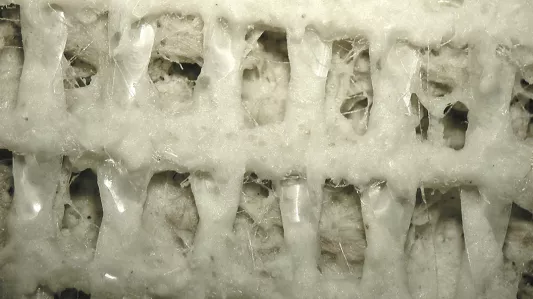

The two images below show untreated carpet backing with proliferous fungal growth compared with carpet backing treated with Microban zinc-based technology. The treated carpet backing is visibly cleaner and fresher.

Molds can also find numerous places in almost any building that meet their preferred growing conditions. We’re all familiar with the never-ending struggle of combatting mold in bathrooms and kitchens, but it can also develop in foam insulation, piping, roofing, underneath floors and carpet, and even behind wallpaper! This is because buildings often contain trapped moisture due to temperature fluctuations, as well as nutrient-dense building materials. Environmentally-responsible zinc-based antifungal technologies offer a potential solution to address this issue and can be incorporated into building materials to disrupt spore growth on surface contact, providing ongoing protection from the deleterious effects of molds, preventing issues from arising.

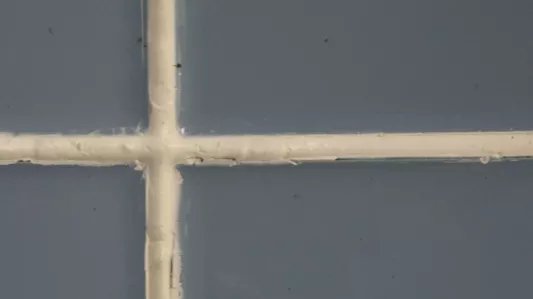

The two images below show untreated grout with proliferous fungal growth compared with grout that is treated with Microban zinc-based technology. The treated tile grout is visibly cleaner with less fungal growth.

Where Can Microban® Zinc Technologies Be Used?

Microban product protection technologies are currently built into over 10,000 products during the manufacturing process, without affecting the attributes that make them appealing to buyers and manufacturers. We currently have over 25 different zinc-based technologies, and our engineers develop and test customized formulations for each individual product. We also have a fungal testing lab that performs a wide range of industry-standard test methods to measure and validate antifungal efficacy, ensuring the best solution for every application. These tests can include the AATCC 30-III Test (resistance of textile materials), AATCC 174-III Test (antifungal treated carpets), ATSM G21 Test (effectiveness of treated polymers), AATCC 30-IV Test (humidity jar with mixed spore suspension), and ASTM D3272 Test (resistance to the growth of mold on the surface of interior coatings in an environmental chamber). Integration of our low- and non-VOC, as well as formaldehyde-free, zinc-based formulations during manufacture, is simple, seamless and does not disrupt existing manufacturing processes, and a specifically developed not to degrade or decrease the aesthetics or functionality of any part of the product.

For example, our ZPTech® formulation offers broad-spectrum protection for textiles, providing up to 99.9% fungal growth inhibition on polyester. It has also been proven to be thermally stable, meaning it’s suitable for use in a variety of manufacturing applications, and for products used in moist, humid environments – from sponges and commercial cleaning trolleys to sealants, cements, paints, and coatings. Our experienced R&D staff work individually with manufacturers to make the integration of ZPTech into their products simple and seamless, usually in the form of a liquid dispersion containing the powered zinc chemistry that can be added directly to the textile dyeing process.

After our whistle-stop tour, we hope you are now more familiar with the antifungal properties of zinc-based additives. Has anything in this blog sparked an interest for your next product? Do you have any further questions about the antifungal properties of zinc-based solutions? Get in contact with our friendly team here at Microban today, and we can work together to formulate a bespoke solution!

1David, R. Why zinc is bad for bacteria. Nature Reviews Microbiology, 2012, 10, 4.

2Pasquet, J, et al. The contribution of zinc ions to the antimicrobial activity of zinc oxide. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2014, 457, 263-274.

3Reeder, NL et al. The antifungal mechanism of action of zinc pyrithione. British Journal of Dermatology, 2011, 2, 9-12.